- 03

- Dec

Epoxy resin pipes are widely used, with obvious advantages and disadvantages

Epoxy resin pipes are widely used, with obvious advantages and disadvantages

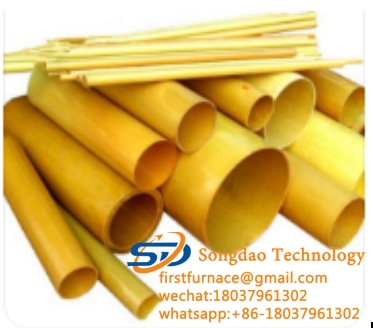

In the building fire protection system, the epoxy resin composite light pipe has a pivotal position. The epoxy resin light pipe must be used in the fire fighting water supply, and it has gradually replaced the galvanized steel pipe. The epoxy resin tube is the main raw material of the epoxy resin light tube, using plastic powder as the coating material, and the plastic layer is melt-coated on its inner surface. The outer surface is melt-coated with a layer of plastic layer or other material anticorrosive layer of rigid plastic composite product. Polyethylene-coated steel pipes and epoxy-coated steel pipes are divided into two types of steel pipes according to different inner coating materials.

Although the use of epoxy resin pipes in building fire protection systems has increased a lot, some of its shortcomings cannot be ignored. One of the most typical is the poor weather resistance, because epoxy resin usually contains aromatic puzzle keyboards, and the cured product has been degraded and broken after being exposed to sunlight. Therefore, the general bisphenol A epoxy resin cured product is easy to be exposed to outdoor sunlight. It loses its luster and gradually chalks up, so it is not suitable for outdoor topcoats. In addition, epoxy resin has poor low-temperature curing performance, and generally needs to be cured above 10 degrees Celsius. If it is below this temperature, it will be very inconvenient for the construction of large objects.