- 08

- Dec

Ulehlukanisa kanjani ikhwalithi yebhodi lokufakelwa kwe-SMC

Ulehlukanisa kanjani ikhwalithi yebhodi lokufakelwa kwe-SMC

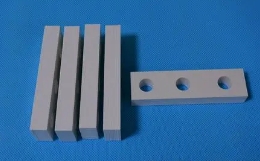

I-insulation board ngokwayo inomsebenzi ogqamile wokufaka u-insulation. Manje isisetshenziswa kakhulu njengezinto zokufakelwa. Izinga lekhwalithi yalo liwukukhathazeka kubathengi. Namuhla, kunabakhiqizi abaningi, futhi ikhwalithi yemikhiqizo nayo ayilingani, ngakho-ke Uma sikhetha, kufanele sinake umehluko. Ake sifundise indlela yokuhlukanisa phakathi kwekhwalithi enhle nembi.

1. Lapho kucaca kakhudlwana ukuhlukaniswa kwebhodi lokufakelwa, ikhwalithi engafaneleki kakhulu, kanye nomuzwa jikelele wokuthi izinga lebhodi elinjalo lifanelekile.

2. I-Dielectric constant: Ipharamitha yokukala ukusebenza kahle. Ubukhulu be-dielectric constant, the more current material will pass under the same condition, and worse umsebenzi we-insulation we-material ehambisanayo. Ngakho-ke, ukuze kuqinisekiswe ukuthi ibhodi le-insulating lingaba ne-insulation evelele, kubaluleke kakhulu ukugcina i-dielectric yayo njalo ngezinga elithile.

3. Ukumelana: Lesi ngesinye sezinkomba eziyinhloko ezisetshenziselwa ukwahlulela umsebenzi wokufakwa kwe-insulation board. Kunemithethonqubo eqinile mayelana nomthamo wemikhiqizo yokufakelwa. Ngokwezidingo ezihlukene zohlelo lokusebenza, kunezicaciso zevolumu ezihlukene. Ngokuvamile, uma kukhulu ukumelana nevolumu, kukhulu ukumelana nendawo yayo

Ibhodi lokufakelwa elihle aligcini nje ngokuba nomsebenzi ovelele wokuvikela, kodwa futhi lingadlala umsebenzi wokumelana nokugqwala nokuvimbela umlilo. Manje ngokukhula okwandayo kocwaningo nokuthuthukiswa kobuchwepheshe, kuthuthukiswe imisebenzi emihle kakhulu yohlelo lokusebenza. Siyathenga Ngalesi sikhathi, kufanele sinake ukuhlukanisa ikhwalithi yomkhiqizo ngokucophelela, inqobo nje uma imikhiqizo yeshidi efanelekayo ingaba nomphumela omuhle wokusebenzisa.