- 23

- Sep

The composition and use skills of skateboard nozzle

The composition and use skills of skateboard nozzle

The sliding nozzle is composed of upper and lower sliding plates and 4 refractory bricks for the upper and lower nozzles. The pouring of each ladle of molten steel must pass through the upper and lower sliding plates and the upper and lower nozzles, so they are very strict. Firstly, they must have sufficient strength at high temperatures to withstand the static pressure of molten steel, and secondly, the upper and lower sliding plates are required. The sliding surface should be very smooth, flatness should be high, to ensure tight contact, to ensure that no molten steel leaks during the pouring process, but also to be resistant to erosion, erosion, and good thermal stability, so as to withstand sudden changes in temperature. Erosion and slag erosion.

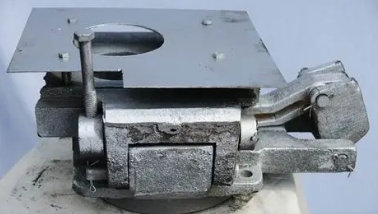

The sliding nozzle device is composed of upper and lower slide plates made of refractory material and a mechanical drive structure, and is installed outside the bottom of the ladle. The upper slide is fixed, and the lower slide is movable. According to the skateboarding method, it can be divided into three categories

1) Linear reciprocating type;

2) Linear propulsion type;

3] Rotary type.

By driving the pull rod, the sliding plate slides back and forth in a straight line. When the casting holes on the upper and lower sliding plate blocks are staggered, the upper nozzle hole is filled with drainage sand, and the ladle can be loaded with steel; when the casting holes overlap, the drainage sand automatically flows out. Pouring, and the pouring speed can be controlled by the degree of overlap of the casting holes.

The sliding plate is a key component that determines the function of the sliding nozzle, and plays a role of controlling and regulating the flow of molten steel. Due to the repeated contact of the sliding plate with high-temperature molten steel (especially the casting hole), the corrosion damage is serious and the use conditions are harsh. The skateboard is required to have good performances such as high strength, corrosion resistance, and peeling resistance. During the casting process, ensure that no molten steel leaks between the skateboards. The skateboard must have the following properties:

(1) Flatness of sliding surface ≤0.05mm;

(2) High mechanical strength;

(3) Strong corrosion resistance to molten steel and molten slag;

(4) Excellent anti-oxidation performance;

(5) Good thermal shock stability.

The sealing protection of the ladle sliding nozzle is mainly at the connection between the upper nozzle and the upper slide, and the lower slide and the lower nozzle. In the pouring process, generally after pouring one or two furnaces of molten steel, the lower slide plate and the nozzle must be replaced and reassembled. The sealing protection adopts fibrous or mortar gaskets to ensure the high cleanliness of the molten steel and the uniformity of the internal quality of the casting slab.