- 25

- Nov

Introduction to the functions and characteristics of the intermediate frequency furnace control panel

Introduction to the functions and characteristics of the intermediate frequency furnace control panel

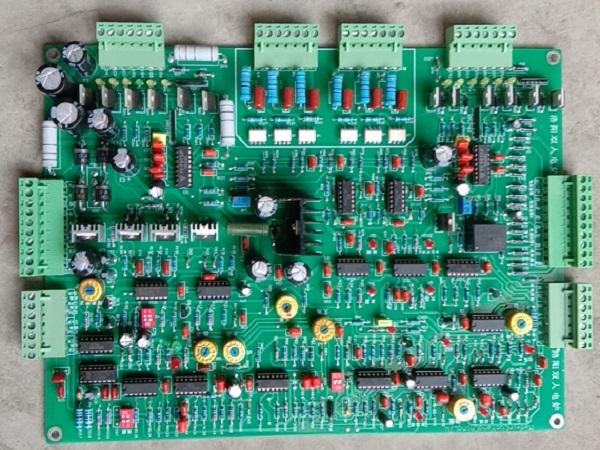

A core accessory of the control panel water intermediate frequency furnace. The intermediate frequency power supply control board is mainly composed of power supply, given regulator, balance regulator, phase shift control circuit, protection circuit, starting calculation circuit, inverter frequency tracking, inverter pulse formation, pulse amplification and pulse transformer. Its core components use high-performance, high-density, ultra-large-scale dedicated DLJ integrated circuits. The following two editors will come to tell you about the functions and characteristics of the intermediate frequency furnace control panel.

One, the function of the intermediate frequency furnace control panel

1. The use of a dedicated and special highly integrated intelligent intermediate frequency furnace control module can not only ensure the versatility and intelligence of the system, but also ensure the stability of the system. Most of the previous intelligent control boards used programmable rewritable devices, such as single-chip, PLC machines, and because of this rewritability, the program content will be destroyed in the environment of large electromagnetic interference with medium frequency induction heating.

2. The pulse width is automatically adjusted. The inverter pulse adopts a variable pulse, and the pulse width is changed according to the different working frequency of the intermediate frequency furnace to prevent the inverter pulse transformer from entering the sub-saturation state. The leading edge of the output pulse is steep, and the waveform is undistorted.

3, double pulse train modulation. The rectification of the intermediate frequency furnace adopts double pulse train modulation, which not only ensures the reliability of the trigger, but also reduces the power consumption of the trigger and improves the stability of the board.

4. The intermediate frequency furnace control panel has strong versatility and is suitable for controlling various intermediate frequency power supplies of 50KW-5000Kw.

5.The onboard phase sequence adaptive circuit adopts three-phase power supply for direct synchronization without a synchronization transformer. The incoming line of the main circuit can be independent of phase sequence.

6. Built-in multi-function protection system. Fully integrated single board, which integrates rectification, inverter, protection, and start control. The intermediate frequency furnace controls the on-board overvoltage, overcurrent, voltage limit, current limit, frequency sweep, frequency lock, intermediate frequency detection, restart, power supply, Various status indications such as the system have the advantages of high reliability, high precision, easy debugging, few relay components, etc., intuitive adjustment and convenient maintenance.

7. The “RE” intelligent port integrates functions such as “start”, “stop”, “reset”, and “remote control”, making the operation of the equipment simple and intelligent.

8. The rectifier synchronous voltage of the intermediate frequency furnace has a wide adaptable range, and it can work normally from 220V to 750V.

9. Buffer start and perfect start detection system, so that this line can realize full power start (start at any position of the power potentiometer)

10. Except for the inverter’s final intermediate frequency furnace driver, all are integrated into a printed circuit board, with few peripheral accessories, no relay components, simple circuit, simple debugging, and convenient maintenance. Once the control system fails, just replace the spare board. However, it will not affect normal production.

Second, the characteristics of the control panel of the intermediate frequency furnace

1, the control circuit is concentrated on the printed board

All the control circuits of the intermediate frequency furnace are on a printed board, which greatly reduces the failures caused by poor contact of the connectors. The start mode of the intermediate frequency furnace is a sweep frequency zero start, which means that the load voltage and current gradually increase from zero during the power start process, so there is no current impact on the power grid. The starting circuit is equipped with an automatic repeated starting circuit, which can prevent the occasional starting failure of the power supply and make the starting success rate 100%. The frequency tracking circuit adopts the average sampling scheme, which improves the anti-interference ability of the inverter. Key electrical components The parameters are determined by computer simulation, and have higher accuracy and reliability than the classical method design through practice.

2, the inverter bridge load is a parallel resonant circuit

The main circuit inverter bridge load of the intermediate frequency furnace is a parallel resonant circuit composed of an induction furnace and a capacitor. In the induction furnace circuit of the intermediate frequency furnace, a capacitor of the same capacity is connected to boost the voltage so that the voltage reaching the furnace is 1500V.

3, misoperation will not affect the system

The power transmission and power-off sequence of the main circuit and control circuit of the intermediate frequency furnace and the misoperation of the user will not have any adverse effects on the system. The specific protection functions are: phase failure protection; overcurrent protection; overvoltage protection; undervoltage Protection; water-off protection under water pressure. The system has complete protection functions, and has an audible and visual alarm when any fault occurs, and the device automatically stops working at the same time.

4, using three-phase fully controlled bridge rectifier

The rectification part of the intermediate frequency furnace control board adopts three-phase full-control bridge rectification, the control loop adopts the current domestic integrated circuit, and the digital trigger circuit with good pulse consistency and strong anti-interference ability. The inverter adopts sweep frequency zero-voltage soft start, and is equipped with a repeated start circuit, thereby improving the reliability of starting. As long as the load quality factor is greater than or equal to 2.5, the startup success rate can reach 100%, and the frequency tracking circuit adopts the average sampling scheme, thereby improving the anti-interference ability of the inverter system. In addition, an automatic inverter θ angle adjustment circuit and an impedance regulator are added to the inverter circuit, which can achieve power output under any load condition, so as to save time, save electricity, and improve the power factor of the grid.