- 29

- Nov

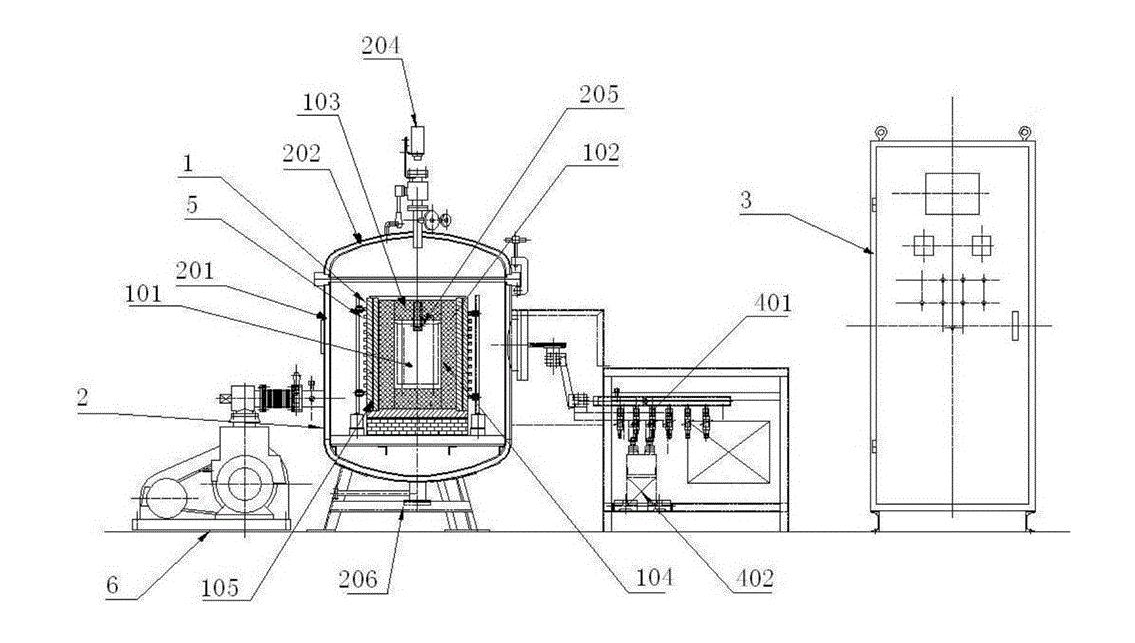

Graphene graphitization furnace

Graphene graphitization furnace

1) The furnace body is of vertical and horizontal structure. The cover is opened on the vertical furnace body, and the front and rear doors are opened horizontally. The double-layer water-cooled structure is adopted. The inner tank is made of 304 stainless steel.

Cooling water is passed through the interlayer. The furnace body can not only be evacuated, but also can be operated with protective gas.

2) The furnace body is equipped with an air extraction interface (for connection with a vacuum pump), an electrode flange opening, an infrared temperature measuring hole, an air outlet, etc. The height of the base in the furnace can be adjusted to adapt to different sensor heights.

3) The furnace cover adopts manual hydraulic lifting and rotating to open the cover. The operation is more labor-saving and convenient than manual wheel operation. The top of the furnace cover is equipped with observation holes, temperature measuring holes and air inlets.

4) The furnace body is equipped with an insulation layer, and a crucible in the furnace. Sensor, corundum.

3. Sensor

The inductor is made of high-quality square copper tube, with low magnetic leakage and high efficiency. The sensor fixing support bar is made of stainless steel and will not be carbonized at high temperature. Aipud, Hunan.

4. Resonant capacitor

The resonant capacitor adopts a water cooling structure, while leaving a margin of 30%.

5. Infrared thermometer

An imported infrared thermometer is used to observe the temperature on the crucible in the furnace in real time.

The infrared temperature measuring probe adopts an imported two-color infrared thermometer, which can perform very accurate measurement even when there is a certain amount of smoke, dust and other particles in the furnace to block the target.

6. Vacuum acquisition system

It is composed of a direct-coupled mechanical pump, an inflatable solenoid vacuum valve, a vacuum butterfly valve, a diaphragm valve and a pipeline. 1 vacuum diaphragm valve is used to fill process gas, 1 is used to open

The front of the furnace door is filled with air to break the vacuum.

7. Electrical control system

The temperature control instrument uses a 0.1% level intelligent segmented program to control the regulator. The instrument can store 50 sections of heating programs and can optionally be equipped with a communication port. With PLC protection, it can monitor the lack of phase, water pressure, circuit, protective gas, vacuum pump, furnace temperature, cabinet temperature, etc., and realize the sequential control and chain protection of power supply, furnace body, cooling water, protective gas and other devices, as well as early warning and alarm And other functions. If the temperature of the furnace body exceeds 60 degrees, an alarm will be issued. The vacuum unit is short of water and stops running after a delay; the vacuum alarm cannot be reached.