- 04

- Dec

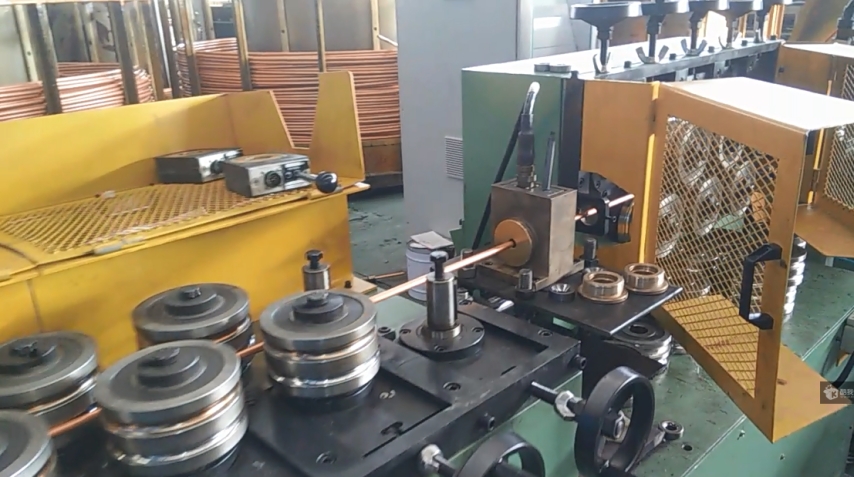

Technical parameters of copper tube induction heating continuous annealing production line

Technical parameters of copper tube induction heating continuous annealing production line

| Serial number | name | Specification | Remark | ||

| 1 | Heating material | Copper and copper | |||

| 2 | OD of annealed pipe | Φ6.0—22.0mm | |||

| 3 | Maximum wall thickness | 0.3-2.0mm | |||

| 4 | Annealing rate | 30~400m/min | |||

| 5 | Total power of intermediate frequency power supply | 400KW | |||

| 6 | Maximum annealing temperature of pipe | 550°C | |||

| 7 | Normal annealing temperature of pipe | 400-450°C | |||

| 8 | Basket specifications | Φ3050×1500mm | |||

| 9 | Maximum material weight | 600kg | |||

| 10 | Maximum rewinding and unwinding drive capacity: | 2000kg (copper tube + basket) | |||

| 11 | Quality standard of copper tube after annealing: | Comply with current national standards | |||

| 12 | Rewinding and unwinding roller table | Two stations | |||

| 13 | Total power of control power supply | 90kW | |||

| 14 | Total installed power of the unit | 900kw | |||

| 15 | Total equipment weight | 30T | |||

| 16 | Hydraulic system pressure | 100kgf/cm2 | |||

| 17 | Hydraulic system flow | 10L/min | |||

| 18 | Compressed air pressure | 4-7kgf/cm2 | |||

| 19 | Compressed gas consumption | 120-200Nm3/h | |||

| 20 | Nitrogen pressure | 3-5kgf/cm2 | |||

| 21 | Nitrogen flow | 60-80Nm3/h | |||

| 22 | Power closed loop cooling tower | ||||

| 23 | Open loop cooling tower | ||||

| 24 | Land area

|

Unit width 12620mm

Unit center height 1100mm Unit length 27050 mm The total height of the unit 2200mm Rewinding and unwinding center distance 24000 mm |

|||

| 25 | Total installed capacity (1000kW) | ||||

| Furnace type | Total power of intermediate frequency power supply | Total motor power | Control power | total capacity | |

| TL400/×400 | 2×400 | 80 | 10 | 900 | |

https://songdaokeji.cn/13909.html

https://songdaokeji.cn/13890.html