- 14

- Dec

The latest production technology of epoxy glass fiber rod for induction melting furnace

The latest production technology of epoxy glass fiber rod for induction melting furnace

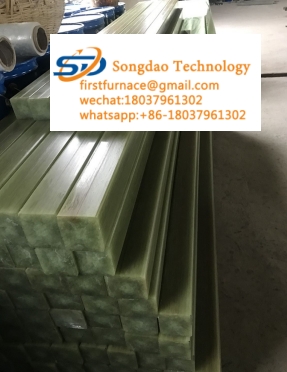

Epoxy glass fiber rods for induction melting furnaces are widely used in the power, electrical, and electrical industries. This is closely related to the good insulation and corrosion resistance of epoxy rods, and the emergence of the latest production technology of epoxy rods Meet the requirements of these industries for product quality.

The specifications of epoxy glass fiber rods for induction melting furnaces are large and small, and only in this way can they be suitable for the needs of products in all walks of life. The production of small rods is relatively easy, but large rods are prone to cracking during the process of tensile resistance. In order to improve the problems that occur in the production process of large rods, it is necessary to improve and innovate the production process to ensure the quality of the product. .

The selection of materials in the latest production process of epoxy glass fiber rods for induction melting furnaces is the first and most important step. In addition to epoxy resin and curing agent, alkali-free and twist-free glass fibers must be selected with the best quality. The dipping time must be mastered well, not too long or too short. Strict accidents occurred during the process of heating, curing and shaping, and the final cutting was successful.