- 18

- Dec

Comparison of the performance of hot blast stove using different shaped lattice refractory bricks

Comparison of the performance of hot blast stove using different shaped lattice refractory bricks

Recently, authoritative experts on refractory materials have conducted experiments on the comparison of the performance of refractory bricks with different shapes of lattices in hot blast stoves. The thermal efficiency of the hot blast stove is also closely related to the design of the lattice refractory bricks. The larger the total surface area of the lattice bricks per unit volume, the higher the mat exchange efficiency.

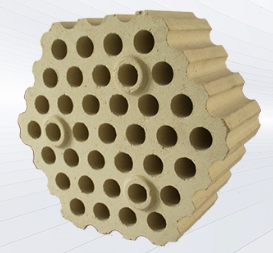

According to experts, traditionally, checker bricks for hot blast stoves are built with rectangular refractory bricks, but due to low thermal efficiency, they have been replaced by other bricks with high efficiency. The commonly used checker bricks can be divided into 4 categories, as shown in the figure below. Each of them can be divided into two types: standard type and high-efficiency type. Some geometric parameters of various checker bricks are listed in the table.

High-efficiency lattice refractory bricks have a larger heating area, so the thermal efficiency is higher. However, due to their thin brick walls, deformation may occur. At the same time, due to the small flue, the pressure loss is large, which is easy to cause blockage. Therefore, high-efficiency checker bricks should be made of refractory materials, and corresponding purification measures should be taken to blast furnace explosion gas.