- 28

- Dec

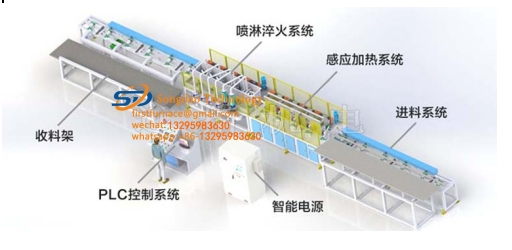

Induction hardening equipment

Induction hardening equipment

udstyr til hærdning af induktion adopts intermediate frequency power supply to control its characteristics:

1. Series resonance design, fully open rectification, high power factor and small resonance component.

2. T2 red copper copper bars are used in the cabinet, which have been sandblasted and passivated to achieve low leakage inductance, anti-oxidation, and effectively reduce line loss.

3. Intelligent quality system monitoring system: real-time monitoring of power supply operating status, database, flexible storage and viewing of process parameters.

4. Parallel resonans design, faseskift og effektjustering, udstyret er modent og stabilt; den har flere fordele i højeffektområdet over 3000KW.

5. DSP kontrol, hurtig indfangningsfaselås start, møder hyppig start og stop, høj succesrate.

6. Frequency conversion and variable load adaptation, frequency adaptation range 200-10000Hz, automatic matching for induction furnace replacement, no manual adjustment is required.

The induction hardening equipment adopts PLC control features:

●The induction hardening heat treatment equipment provides a remote console with a touch screen or an industrial computer system according to user needs.

●Særlig tilpasset menneske-maskine-grænseflade, meget brugervenlig betjeningsinstruktion, en person kan betjene hele udstyrssættet, hvilket sparer arbejdskraft og omkostninger.

●Fulddigitale parametre, der kan justeres i høj dybde, så længe emnets ståltype, størrelse og udstyr er indtastet, kaldes de relevante parametre automatisk uden manuel registrering, rådgivning og input. Har en historiekurvefunktion med høj præcision. Det kan sikkerhedskopieres af U-disk eller netværk, og dataene kan gemmes permanent.

●Strict grade management system, induction hardening equipment is equipped with one-key reduction system. (If there is a problem in the adjustment, or you want to restore the device to its original state, just press a button to restore the original data)