- 28

- Dec

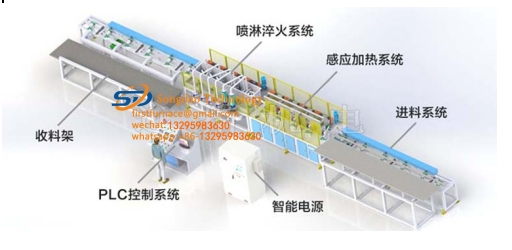

Induction hardening equipment

Induction hardening equipment

The akụrụngwa na-eme ka ike ghara ịrụ ọrụ adopts intermediate frequency power supply to control its characteristics:

1. Series resonance design, fully open rectification, high power factor and small resonance component.

2. T2 red copper copper bars are used in the cabinet, which have been sandblasted and passivated to achieve low leakage inductance, anti-oxidation, and effectively reduce line loss.

3. Intelligent quality system monitoring system: real-time monitoring of power supply operating status, database, flexible storage and viewing of process parameters.

4. Ndekota resonance imewe, oge mgbanwe na ike mgbanwe, akụrụngwa bụ tozuru okè na kwụsie ike; ọ nwere uru ndị ọzọ na oke ike dị elu karịa 3000KW.

5. DSP njikwa, ngwa ngwa njide oge mkpọchi mmalite, izute mmalite na nkwụsịtụ ugboro ugboro, ọnụego ọganihu dị elu.

6. Frequency conversion and variable load adaptation, frequency adaptation range 200-10000Hz, automatic matching for induction furnace replacement, no manual adjustment is required.

The induction hardening equipment adopts PLC control features:

●The induction hardening heat treatment equipment provides a remote console with a touch screen or an industrial computer system according to user needs.

●Special ahaziri mmadụ-igwe interface, ukwuu ọrụ-enyi na enyi ntuziaka ọrụ ntuziaka, otu onye nwere ike rụọ ọrụ dum set nke ngwá, na-azọpụta ọrụ na-eri.

●Dịjitalụ niile, ihe omimi dị elu na-agbanwe agbanwe, ọ bụrụhaala na ụdị ígwè, nha, na ngwá ọrụ nke workpiece bụ ntinye, a na-akpọ ihe ndị dị mkpa na-akpaghị aka, na-enweghị ndekọ akwụkwọ ntuziaka, nyocha, na ntinye. Nwere ọrụ okirikiri akụkọ ihe mere eme dị elu. Enwere ike kwado ya site na diski U ma ọ bụ netwọkụ, yana enwere ike ịchekwa data ahụ kpamkpam.

●Strict grade management system, induction hardening equipment is equipped with one-key reduction system. (If there is a problem in the adjustment, or you want to restore the device to its original state, just press a button to restore the original data)