- 28

- Dec

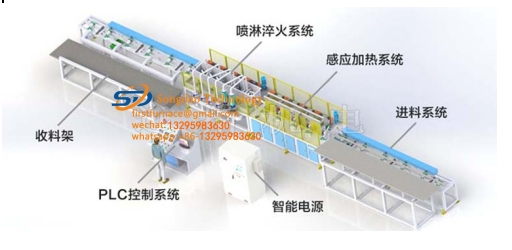

Induction hardening equipment

Induction hardening equipment

ໄດ້ ອຸປະກອນແຂງ adopts intermediate frequency power supply to control its characteristics:

1. Series resonance design, fully open rectification, high power factor and small resonance component.

2. T2 red copper copper bars are used in the cabinet, which have been sandblasted and passivated to achieve low leakage inductance, anti-oxidation, and effectively reduce line loss.

3. Intelligent quality system monitoring system: real-time monitoring of power supply operating status, database, flexible storage and viewing of process parameters.

4. ການອອກແບບ resonance ຂະຫນານ, ການປ່ຽນໄລຍະແລະການປັບພະລັງງານ, ອຸປະກອນແມ່ນແກ່ແລະຄວາມຫມັ້ນຄົງ; ມັນມີຄວາມໄດ້ປຽບຫຼາຍໃນລະດັບພະລັງງານສູງກວ່າ 3000KW.

5. ການຄວບຄຸມ DSP, ໄວ capture ໄລຍະການລັອກເລີ່ມຕົ້ນ, ຕອບສະຫນອງການເລີ່ມຕົ້ນແລະຢຸດເລື້ອຍໆ, ອັດຕາຜົນສໍາເລັດສູງ.

6. Frequency conversion and variable load adaptation, frequency adaptation range 200-10000Hz, automatic matching for induction furnace replacement, no manual adjustment is required.

The induction hardening equipment adopts PLC control features:

●The induction hardening heat treatment equipment provides a remote console with a touch screen or an industrial computer system according to user needs.

●ການໂຕ້ຕອບເຄື່ອງຜູ້ຊາຍທີ່ກໍາຫນົດເອງພິເສດ, ຄໍາແນະນໍາການດໍາເນີນງານທີ່ເປັນມິດກັບຜູ້ໃຊ້ສູງ, ບຸກຄົນຫນຶ່ງສາມາດດໍາເນີນການອຸປະກອນທັງຫມົດ, ປະຫຍັດແຮງງານແລະຄ່າໃຊ້ຈ່າຍ.

●ຕົວກໍານົດການປັບລະດັບດິຈິຕອນທັງຫມົດ, ຄວາມເລິກສູງ, ຕາບໃດທີ່ປະເພດເຫຼັກ, ຂະຫນາດ, ແລະອຸປະກອນຂອງ workpiece ໄດ້ input, ຕົວກໍານົດການທີ່ກ່ຽວຂ້ອງຈະຖືກເອີ້ນອັດຕະໂນມັດ, ໂດຍບໍ່ມີການບັນທຶກຄູ່ມື, ໃຫ້ຄໍາປຶກສາ, ແລະການປ້ອນຂໍ້ມູນ. ມີຟັງຊັນເສັ້ນໂຄ້ງປະຫວັດສາດທີ່ມີຄວາມແມ່ນຍໍາສູງ. ມັນສາມາດໄດ້ຮັບການສໍາຮອງຂໍ້ມູນໂດຍ U disk ຫຼືເຄືອຂ່າຍ, ແລະຂໍ້ມູນສາມາດເກັບຮັກສາໄວ້ຢ່າງຖາວອນ.

●Strict grade management system, induction hardening equipment is equipped with one-key reduction system. (If there is a problem in the adjustment, or you want to restore the device to its original state, just press a button to restore the original data)