- 10

- Dec

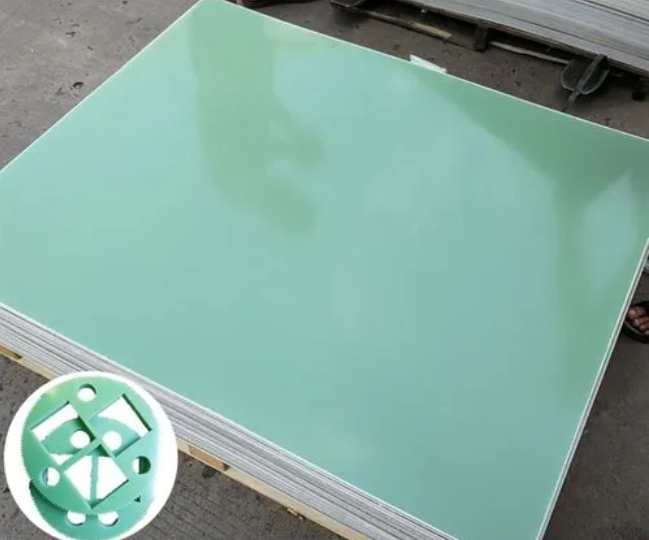

Taw qhia rau cov yam ntxwv ntawm 3240 epoxy resin board

Taw qhia rau cov yam ntxwv ntawm 3240 epoxy cob board

1. Ntau hom ntawv

Ntau yam resins, curing agents, thiab modifier systems yuav luag hloov mus rau qhov yuav tsum tau ntawm ntau yam kev siv ntawm daim ntawv, thiab qhov ntau yuav yog los ntawm tsawg viscosity mus rau siab melting point solids.

2. Muaj zog adhesion

Lub hauv paus ntsiab lus ntawm polar hydroxyl pawg thiab ether bonds nyob rau hauv cov saw molecular ntawm epoxy resins ua rau nws nplaum heev rau ntau yam khoom. Lub shrinkage ntawm epoxy resin yog tsawg thaum kho, thiab cov kev ntxhov siab sab hauv tsim yog me me, uas kuj pab txhim kho lub zog adhesion.

3. Yooj yim kho

Xaiv ntau yam tshuaj tua kab mob sib txawv, cov txheej txheem epoxy resin tuaj yeem yuav luag kho tau hauv qhov kub ntawm 0 ~ 180 ℃.

4. Mechanical zog

Cov kho epoxy resin system muaj cov cuab yeej zoo heev.

5. Tsawg shrinkage

Cov tshuaj tiv thaiv ntawm epoxy resin thiab tus neeg sawv cev kho siv yog ua los ntawm cov tshuaj tiv thaiv ncaj qha los yog lub nplhaib-qhib polymerization cov tshuaj tiv thaiv ntawm epoxy pawg nyob rau hauv cov molecule resin, thiab tsis muaj dej los yog lwm yam khoom los ntawm cov khoom tsis haum. Piv nrog unsaturated polyester resins thiab phenolic resins, lawv pom tsawg heev shrinkage (tsawg dua 2%) thaum kho.

6. Ruaj khov

Cov qauv yog ci hauv qhov cub rau 24 teev ntawm qhov ntsuas kub uas tau teev tseg los ntawm qhov ntsuas. Qhov saum npoo ntawm cov qauv yuav tsum tsis txhob blistered, thiab yuav tsum tsis txhob muaj kab nrib pleb tshaj 10mm tob ntawm ntug.

7. Flammability

Kuj tseem hu ua nplaim taws retardancy, nws tus kheej tua hluav taws tsis kam, nplaim taws retardancy, hluav taws tsis kam, flammability thiab lwm yam combustibility yog ntsuas lub peev xwm ntawm cov khoom los tiv thaiv combustion.