- 10

- Dec

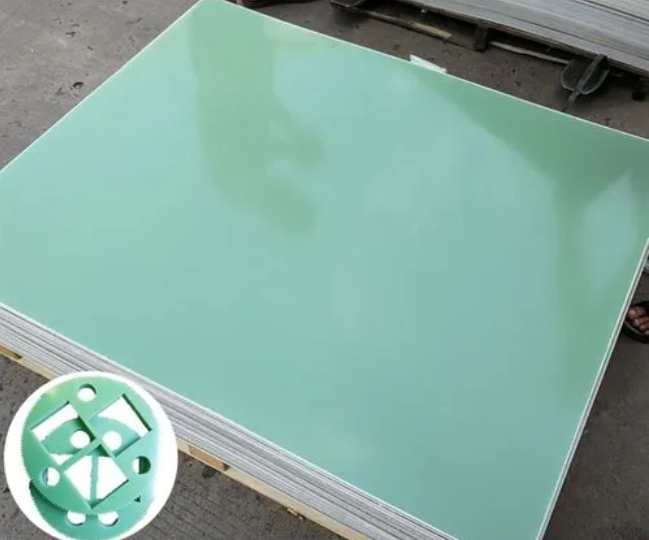

Introduction to the characteristics of 3240 epoxy resin board

Introduction to the characteristics of 3240 dewan résin epoxy

1. Various forms

Various resins, curing agents, and modifier systems can almost adapt to the requirements of various applications on the form, and the range can be from very low viscosity to high melting point solids.

2. Strong adhesion

The inherent polar hydroxyl groups and ether bonds in the molecular chain of epoxy resins make it highly adhesive to various substances. The shrinkage of epoxy resin is low when curing, and the internal stress generated is small, which also helps to improve the adhesion strength.

3. Convenient curing

Choose a variety of different curing agents, the epoxy resin system can almost be cured in the temperature range of 0 ~ 180 ℃.

4. Mechanical properties

The cured epoxy resin system has excellent mechanical properties.

5. Lemes nyusutan

The reaction between the epoxy resin and the curing agent used is carried out by direct addition reaction or ring-opening polymerization reaction of epoxy groups in the resin molecule, and no water or other volatile by-products are emitted. Compared with unsaturated polyester resins and phenolic resins, they show very low shrinkage (less than 2%) during curing.

6. stabilitas termal

The sample is baked in an oven for 24 hours at the temperature specified by the index. The surface of the sample should not be blistered, and there should be no cracks over 10mm deep on the edge.

7. Flammability

Also known as flame retardancy, self-extinguishing flame resistance, flame retardancy, fire resistance, flammability and other combustibility is to assess the ability of the material to resist combustion.