- 03

- Mar

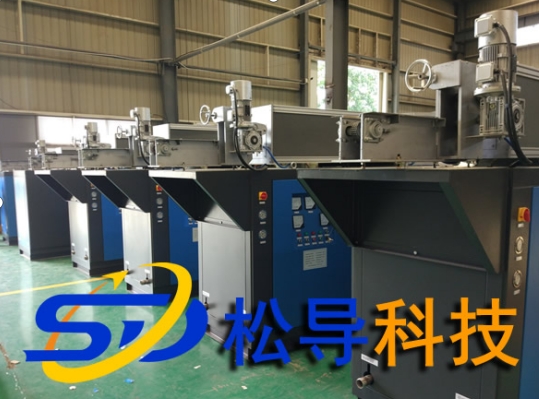

Koj puas to taub lub hom ntawm Suav induction cua sov rauv?

Koj puas to taub lub hom ntawm Suav induction cua sov rauv?

Lub zog txuag ntawm Tuam Tshoj induction cua sov cua sov yog embodied nyob rau hauv lub ceev cua kub ceev, high efficiency efficiency, tsawg oxidation thiab decarbonization, txuag cov ntaub ntawv thiab cov nqi, thiab ncua lub neej ntawm pwm.

Vim lub exquisite tsim ntawm Tuam Tshoj lub induction cua sov rauv, cov ntaub ntawv exquisite siv thiab tsis muaj tej fab, lub cua sov ceev, chav tsev zog noj, khoom siv kev cia siab rau thiab yooj yim ntawm kev khiav hauj lwm ntawm Tuam Tshoj lub induction cua sov rauv tau zoo heev txhim kho, deb tshaj domestic counterparts. Vim lub cua sov ceev ntawm Tuam Tshoj lub induction cua sov rauv, muaj tsawg heev oxidation. Cov oxidation hlawv poob ntawm forgings rhuab los ntawm induction cua sov rauv tsuas yog 0.5%, oxidation burning poob ntawm lub cub tawg cua sov yog 2%, thiab cov thee hluav taws xob furnaces yog 3%. Induction cua sov Lub tshuab cua sov txheej txheem txuag cov ntaub ntawv, thiab txhua tuj ntawm forgings txuag tsawg kawg yog 20-50 kilograms ntawm steel raw cov ntaub ntawv piv nrog cov thee hluav taws xob furnaces. Nws cov khoom siv tus nqi tuaj yeem ncav cuag 95%.

2. Vim yog cov cua sov ntawm Tuam Tshoj lub induction cua sov rauv, siab kub tswj qhov tseeb, thiab tsis tshua muaj kub qhov sib txawv ntawm cov tub ntxhais thiab nto, lub neej ntawm forging tuag yog zoo heev nyob rau hauv forging, thiab lub roughness ntawm forging nto kuj tsawg. ua 50um. Cov txheej txheem txuag hluav taws xob, induction cua sov rauv cua sov Piv nrog cov roj cua kub hnyav, nws tuaj yeem txuag hluav taws xob los ntawm 31.5% ~ 54.3%, thiab nws tuaj yeem txuag hluav taws xob los ntawm 5% ~ 40% piv nrog cov cua sov. Cov cua kub zoo yog qhov zoo, uas tuaj yeem txo qhov kev tsis lees paub los ntawm 1.5%, nce tus nqi ntau lawm los ntawm 10% -30%, thiab ncua lub neej ntawm pwm los ntawm 10% -15%.

3. Tuam Tshoj lub induction cua sov rauv ua tau raws li qhov tseem ceeb ntawm kev tiv thaiv ib puag ncig tam sim no, muaj kev ua haujlwm zoo tshaj plaws, txhim kho kev ua haujlwm ntawm cov neeg ua haujlwm thiab lub tuam txhab cov duab, tsis muaj kuab paug, thiab muaj kev siv hluav taws xob tsawg. Piv nrog rau cov qhov cub hluav taws xob hauv Suav teb, cov neeg ua haujlwm yuav tsis raug ci thiab haus luam yeeb los ntawm cov qhov cub hluav taws xob hauv qab lub hnub ci, thiab tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm ntau yam kev ntsuas ntawm lub tuam tsev tiv thaiv ib puag ncig, thiab tib lub sijhawm tsim lub tuam txhab cov duab sab nrauv thiab yav tom ntej. kev loj hlob ntawm forging kev lag luam. sib. Tuam Tshoj tus induction cua sov rauv yog ib tug kuj muaj zog-txuag cua sov txoj kev ntawm hluav taws xob cua sov rauv. Lub zog noj ntawm forgings ib tuj los ntawm chav tsev kub txog 1100 ° C tsuas yog 360 degrees.