- 03

- Mar

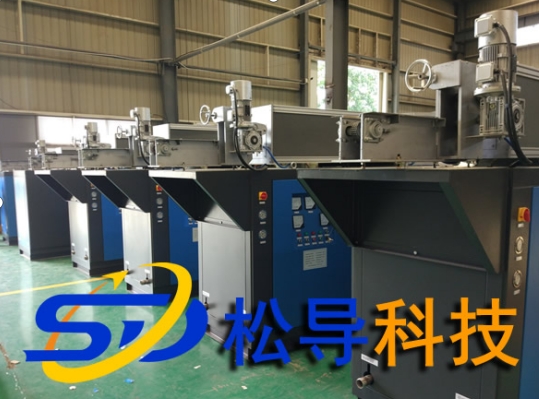

Do you understand the brand of Chinese induction heating furnace?

Do you understand the brand of Chinese induction heating furnace?

The energy saving of China’s indüksiyon isitish pechkasi is embodied in the fast heating speed, high production efficiency, less oxidation and decarbonization, saving materials and costs, and extending the life of the mold.

Due to the exquisite design of China’s induction heating furnace, the exquisite materials used and no cutting corners, the heating speed, unit power consumption, equipment reliability and convenience of operation of China’s induction heating furnace have been greatly improved, far surpassing domestic counterparts. Due to the fast heating rate of China’s induction heating furnace, there is very little oxidation. The oxidation burning loss of forgings heated by induction heating furnace is only 0.5%, the oxidation burning loss of gas furnace heating is 2%, and that of coal-fired furnaces is 3%. Induction heating The furnace heating process saves materials, and each ton of forgings saves at least 20-50 kilograms of steel raw materials compared with coal-fired furnaces. Its material utilization rate can reach 95%.

2. Due to the uniform heating of China’s induction heating furnace, high temperature control accuracy, and extremely small temperature difference between core and surface, the life of the forging die is greatly increased in forging, and the roughness of the forging surface is also less than 50um. Process energy saving, induction heating furnace heating Compared with heavy oil heating, it can save energy by 31.5%~54.3%, and it can save energy by 5%~40% compared with gas heating. The heating quality is good, which can reduce the rejection rate by 1.5%, increase the production rate by 10%-30%, and extend the life of the mold by 10%-15%.

3. China’s induction heating furnace meets the current major environmental protection requirements, has a superior working environment, improves the labor environment of workers and the company’s image, is pollution-free, and has low energy consumption. Compared with coal stoves in China, workers will no longer be bake and smoked by coal stoves under the scorching sun, and can meet the requirements of various indicators of the environmental protection department, and at the same time establish the company’s external image and the future development of the forging industry. trend. China’s induction heating furnace is a relatively energy-saving heating method among electric heating furnaces. The power consumption of forgings per ton from room temperature to 1100°C is only 360 degrees.