- 29

- Jul

Sab saum toj ntawm lub pas dej molten ntawm lub qhov cub induction melting ua “hump” txoj cai ua haujlwm

- 29

- Jul

- 29

- Jul

Sab saum toj ntawm lub pas dej molten ntawm lub induction melting rauv tsim ib txoj hauv kev ua haujlwm “hump”.

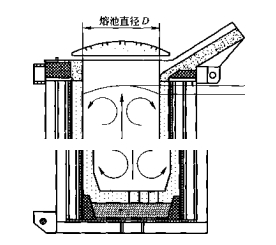

Nyob rau hauv cov txheej txheem smelting ntawm lub induction melting rauv, thaum cov khoom hlau yog melted, lub yaj yuav tsim ib tug tsis tu ncua txav nyob rau hauv qhov kev txiav txim ntawm electromagnetic quab yuam. Qhov kev txav no pib los ntawm qhov chaw ntawm lub pas dej molten thiab txav mus rau ob qhov kawg ntawm lub kauj. Vim hais tias cov hlau yog txwv los ntawm lub cub tawg hauv qab thiab lub qhov cub phab ntsa, qhov kawg txav yog ib txwm nce mus, tsim ib tug “hump” nyob rau sab saum toj ntawm lub molten pas dej ua ke. Qee cov ntaub ntawv siv qhov sib piv ntawm qhov siab ntawm lub hump mus rau txoj kab uas hla ntawm lub pas dej molten los qhia txog lub zog nplawm ntawm lub pas dej molten. Cov tsos ntawm “hump” yog qhia hauv daim duab 2-9.

Daim duab 2-9 Schematic daim duab ntawm “hump” morphology ntawm cov yaj nyob rau hauv lub induction melting rauv

Txawm li cas los xij, txhawm rau qhia meej cov duab ntawm “hump” ntawm lub qhov cub induction melting rauv, thiab kom nthuav tawm cov dej ntws thiab deformation tus cwj pwm ntawm cov kua hlau nyob rau hauv qhov kev txiav txim ntawm electromagnetic teb, nws yog ib qho tsim nyog los daws qhov sib npaug Maxwell (coupled nrog Ohm’s. txoj cai) kom tau txais lub zog electromagnetic. Lub electromagnetic quab yuam ntawm yog hloov mus rau hauv Navier-Stokes kab zauv thiab continuity equation raws li ntim quab yuam kom tau tus khiav ceev thiab dawb saum npoo. Nyob rau tib lub sijhawm, thaum lub ntsej muag dawb ntawm cov yaj hloov pauv, nws yuav ua rau muaj kev cuam tshuam rau kev faib tawm ntawm electromagnetic teb nyob rau hauv cov yaj, thiab tom qab ntawd cuam tshuam rau lub zog electromagnetic hauv cov yaj, uas yuav hloov pauv qhov dawb saum npoo thiab kev faib tawm. ntawm cov yaj. , Nws tuaj yeem pom tias qhov chaw ntws thiab qhov chaw electromagnetic yog qhov sib txuas ua ke.

Txhawm rau kom tau txais cov morphology ntawm cov yaj “hump” hauv lub xeev sib npaug thiab ua kom yooj yim rau cov txheej txheem suav, cov kev xav hauv qab no tuaj yeem ua rau lub qhov cub induction melting:

(1) Vim yog cov nyhuv ntawm daim tawv nqaij, qhov kev nkag mus tob 3 tam sim no me dua qhov loj ntawm qhov nce thiab cov hlau yaj. Yog li ntawd, lub electromagnetic quab yuam ua nyob rau hauv lub yaj yuav suav hais tias yog ib tug deg quab yuam thiab yuav tsum tau qhia los ntawm ib tug sib nqus stress tensor (magnetic stress tensor);

(2) Kev hloov pauv morphological ntawm yaj “hump” tsis cuam tshuam rau kev faib cov kab sib nqus ntawm lub zog hauv cov yaj;

(3) Yog hais tias nws yog ib qho kev sib cais tooj liab qwj, txij li cov electromagnetic teb tsuas tuaj yeem nkag mus rau hauv cov yaj los ntawm qhov sib txawv ntawm qhov sib cais lobes, qhov kawg ntawm electromagnetic teb yog me me heev. Yog li ntawd, lub electromagnetic induction nyob rau hauv lub split tooj liab nce Qhov kev siv yog xam raws li lub electromagnetic induction siv nyob rau hauv lub infinite solenoid. Thaum lub kaw lus nce mus txog qhov sib npaug, qhov nro ntawm lub hump, lub siab zoo li qub ntawm cov yaj thiab qhov nruab nrab ntawm qhov sib npaug ntawm qhov sib npaug ntawm electromagnetic deg quab yuam mus txog qhov sib npaug.