- 09

- Oct

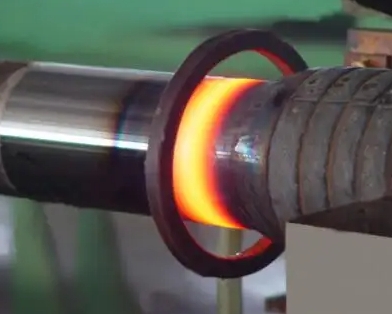

Vim li cas qhov kev kho cua sov ntawm steel hexagonal hniav nrog cov khoom siv quenching siab ua rau tawg?

Vim li cas thiaj li kho cua sov ntawm steel hexagonal hniav nrog cov khoom siv hluav taws xob ntau zaus tsim kev puas tsuaj

Yuav kom ua tau raws li qhov xav tau ntawm kev tsim khoom, peb feem ntau siv cov khoom siv hluav taws xob ntau zaus rau kev kho cua sov. Txawm li cas los xij, hauv kev tsim khoom, nws pom tau tias cov hniav blanking feem ntau tawg thiab ntog ntawm cov ces kaum thiab cov hniav puas lawm, ua rau cov pwm ua tsis tiav thiab muab pov tseg. Vim hais tias lub blanking tuag ntawm lub blanking hniav yog nyob rau hauv lub lag luam, nws mas dais cov nyhuv ntawm cov yas deformation tsis kam ntawm lub blanking (35 steel txiv ntseej bar) thiab lub sij hawm lateral M1 thiab M2 generated los ntawm cov khoom tawg tsis kam, uas yog ib qho yooj yim mus ua. lub ces kaum ntawm cov hniav kom tawg thiab tsis. Ntawm qhov tod tes, muaj qhov sib txawv ntawm qhov tuag thiab qhov bar thaum lub sij hawm blanking, uas ua rau lub sij hawm tom qab lub sij hawm blanking, uas yog ib qho yooj yim ua rau lub blanking hniav puas.