- 09

- Oct

Why does the heat treatment of steel hexagonal blade with high frequency quenching equipment produce fracture

Why does the heat treatment of steel hexagonal blade with high frequency quenching equipment produce fracture

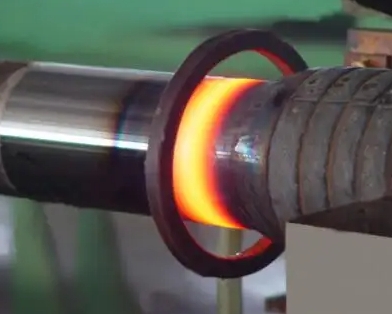

In order to meet the needs of production, we often use high-frequency quenching equipment for heat treatment. However, in production, it is found that the blanking blade often breaks and falls at the corners and the blade is damaged, causing the mold to fail and be scrapped. Because the blanking die on the blanking blade is in operation, it mainly bears the effect of the plastic deformation resistance of the blanking (35 steel nut bar) and the lateral moments M1 and M2 generated by the material breaking resistance, which is easy to cause the corner of the blade to break and fail. On the other hand, there is a gap between the die and the bar during blanking, which causes lateral moment during blanking, which is easy to cause the blanking blade to be damaged.