- 23

- Aug

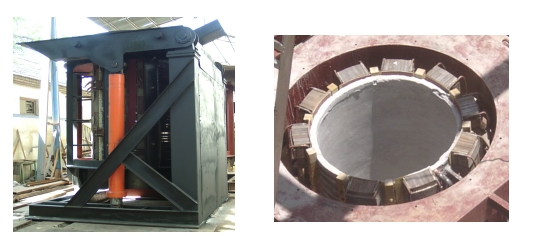

Nhọrọ usoro nchara shei oven ahụ nke induction agbaze ọkụ

Nhọrọ usoro nke ígwè shei oven ozu nke ọkụ na-agbaze ọkụ

1. Ọkụ

Ahụ ọkụ ahụ nwere eriri induction, yok magnetik, etiti ọkụ, cylinder tilting na ndị ọzọ.

Ngwunye ụba

Ejiri eriri ọla kọpa 99.9% mee eriri induction. Igwe mkpuchi induction na-anabata usoro nke ikechi teepu mica na itinye varnish mkpuchi. A na-efesa elu ya na akwa mkpuchi mkpuchi isi awọ, na voltaji na-eguzogide oyi nke mkpuchi mkpuchi karịrị 5000V.

A na-edozi eriri eriri induction site n’ụdị bolts na ihe mkpuchi mkpuchi na-agbado na gburugburu ya. Mgbe emechara eriri igwe, njehie nke ntụgharị ntụgharị ya abụghị karịa

karịa 2mm.

Ma akụkụ nke elu na nke dị ala nke eriri induction nwere mgbanaka igwe anaghị agba nchara na-eme ka mmiri dị jụụ, ebumnuche ya bụ ikpokọta ihe mkpuchi ọkụ ahụ n’ụzọ axial na ogologo ndụ ọrụ nke mkpuchi ọkụ.

Na ntinye mmiri nke eriri induction, a na-etinye ọtụtụ ihe nyocha mmiri dị ka sekit mmiri si dị. Mgbe okpomoku mmiri nke otu ụzọ kpuchiri, enwere ike ịnye oti mkpu ozugbo ma enwere ike mechie ọkụ ọkụ nke etiti na-akpaghị aka.

1.2, yok

The yok bụ nke oyi-akpọrepu silicon ígwè mpempe akwụkwọ na elu permeability. The ọkpụrụkpụ nke silicon ígwè mpempe akwụkwọ bụ 0.3 mm. Yoke na-anabata usoro profaịlụ, na arc nke ime ime bụ otu arc nke gburugburu mpụta nke eriri induction, ka e wee kesaa yoke ahụ nke ọma n’èzí nke eriri induction, nke na-egbochi magnetik na-egbuke egbuke. ogige nke eriri igwe ruo n’ókè kachasị ma na-ebelata sekit magnetik mpụga Magnetoresitance.

A na-ejikọta yoke nke akụkụ ndị na-adịghị ike site na efere igwe anaghị agba nchara na igwe anaghị agba nchara n’akụkụ abụọ ma dozie ya site na ịgbado ọkụ. A na-agbaji ọkpọkọ mmiri jụrụ oyi na efere igwe anaghị agba nchara n’akụkụ abụọ iji mee ka yok dị jụụ. Ọkpụkpọ mmiri jụrụ oyi nwere ike iguzogide nrụgide mmiri 0.45Mpa na-enweghị ntapu n’ime nkeji iri na ise.

Mgbe agbakọtara yok, curvature abụghị ihe karịrị 4mm, na ọdịiche dị n’etiti etiti usoro ihe ọmụma na n’ezie centerline abụghị ihe karịrị 3mm.

A na-etinye efere Teflon na efere rọba asbestos site n’ime ruo n’èzí n’etiti yok na eriri igwe. Mpempe akwụkwọ Teflon nwere ike mkpuchi dị elu na nguzogide okpomọkụ dị elu, na mpempe akwụkwọ asbestos nwere nnukwu nguzogide okpomọkụ. Nke a na-eme ka mkpuchi na mkpuchi okpomọkụ dị n’etiti yok na eriri igwe.

A na-edozi yok nke ọ bụla site na mkpara ịghasa nke etinyere na shei ọkụ ka ọ bụrụ otu ike na-akwali gburugburu gburugburu eriri igwe, nke mere na yok na eriri igwe na-edozi ya, a gaghịkwa emepụta eriri igwe ahụ n’oge agbaze wee pụta. ọkụ. megharia.

1.3. Efere

A na-ekewa etiti ọkụ ọkụ n’ime akụkụ abụọ: mbughari na ofu.

1.3.1, stovu mbughari

A na-eji etiti ọkụ a na-ebugharị ebugharị iji wụnye eriri induction na yok magnetik. A na-eji akụkụ ígwè na efere ígwè welded ya, ma nakwere ihe owuwu etiti maka mmezi dị mfe. Igwe ikpo okwu na-arụ ọrụ n’elu grate a na-ebugharị na-anakwere efere nchara siri ike iji meziwanye ike na ibu ibu nke grate.

1.3.2, hob kwụ ọtọ

A na-etinye oghere ọkụ a kapịrị ọnụ na ntọala ahụ iji buru ihe ọkụ ọkụ na-ebugharị. A na-ejikọta akụkụ elu nke grate a kapịrị ọnụ na grate a na-ebugharị site na oghere na-atụgharị, na grate nke na-ebugharị nwere ike ịgbatị n’ihu site na 95 degrees n’okpuru ntinye nke cylinder mmanụ na-atụgharị.

A na-echekwa ihe nchekwa dị ukwuu na nhazi nke akụkụ grate. Gbaa mbọ hụ na etiti ọkụ ahụ nwere nkwụsi ike zuru oke ma na-agba ọsọ nke ọma mgbe ọ na-ebu ibu kachasị.

1.4 mkpuchi ọkụ

A na-etinye ihe mkpuchi ọkụ n’elu okpoko ọkụ a na-ebugharị. Enwere ike iji aka rụọ ọrụ mkpuchi ọkụ ọkụ na hydraulic.

1.4.1, mkpuchi ọkụ ọkụ ntuziaka

A na-etinye mkpuchi ọkụ ọkụ akwụkwọ ntuziaka n’elu ogwe na-atụgharị n’akụkụ elu nke ọkụ ọkụ ahụ, a pụkwara imeghe mkpuchi ọkụ ọkụ ma mechie ya site na ịkwaga aka elu na ala. Mgbe ị na-akwụ ụgwọ ma ọ bụ na ọ dịghị mkpa iji mkpuchi ọkụ ọkụ, mkpuchi ọkụ nwere ike gbanwee n’akụkụ akụkụ nke akụkụ elu nke ọkụ ọkụ ahụ.

1.4.2. Ihe mkpuchi ọkụ na-ebugharị hydraulic:

A na-etinye mkpuchi mkpuchi ọkụ nke hydraulically na-atụgharị n’elu akụkụ elu nke ọkụ ọkụ ahụ, a na-enwetakwa oghere na ntụgharị nke mkpuchi ọkụ site na omume nke elu na ala mmanụ cylinders na mmanụ mmanụ na-atụgharị. Na-arụ ọrụ site na mgba ọkụ ọrụ na console. Mgbe ị na-akwụ ụgwọ ma ọ bụ na ọ dịghị mkpa iji mkpuchi ọkụ ọkụ, mkpuchi ọkụ nwere ike gbanwee n’akụkụ akụkụ nke akụkụ elu nke ọkụ ọkụ ahụ.