- 28

- Dec

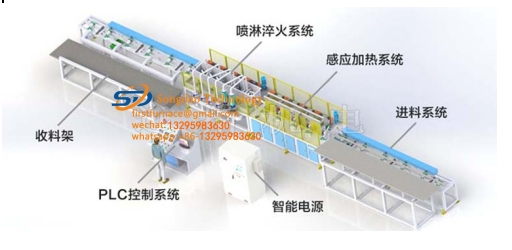

Induction hardening equipment

Induction hardening equipment

The peralatan hardening prabawa adopts intermediate frequency power supply to control its characteristics:

1. Series resonance design, fully open rectification, high power factor and small resonance component.

2. T2 red copper copper bars are used in the cabinet, which have been sandblasted and passivated to achieve low leakage inductance, anti-oxidation, and effectively reduce line loss.

3. Intelligent quality system monitoring system: real-time monitoring of power supply operating status, database, flexible storage and viewing of process parameters.

4. Desain resonansi paralel, owah-owahan fase lan pangaturan daya, peralatan kasebut diwasa lan stabil; wis luwih kaluwihan ing sawetara daya dhuwur ndhuwur 3000KW.

5. kontrol DSP, cepet njupuk phase kunci wiwitan, ketemu Kerep wiwitan lan mungkasi, tingkat sukses dhuwur.

6. Frequency conversion and variable load adaptation, frequency adaptation range 200-10000Hz, automatic matching for induction furnace replacement, no manual adjustment is required.

The induction hardening equipment adopts PLC control features:

●The induction hardening heat treatment equipment provides a remote console with a touch screen or an industrial computer system according to user needs.

●Special selaras antarmuka wong-mesin, Highly pangguna-loropaken instruksi operasi, siji wong bisa operate kabeh pesawat saka peralatan, nyimpen pegawe lan biaya.

●Kabeh-digital, dhuwur-ambane paramèter luwes, anggere jinis baja, ukuran, lan peralatan saka workpiece sing input, paramèter cocog kanthi otomatis disebut, tanpa ngrekam manual, consulting, lan input. Nduwe fungsi kurva riwayat tliti dhuwur. Bisa digawe serep dening U disk utawa jaringan, lan data bisa disimpen permanen.

●Strict grade management system, induction hardening equipment is equipped with one-key reduction system. (If there is a problem in the adjustment, or you want to restore the device to its original state, just press a button to restore the original data)