- 23

- Feb

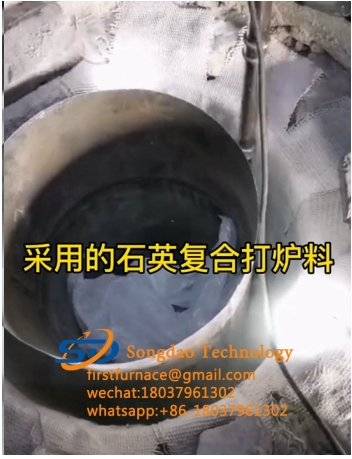

How to knot the bottom of induction melting furnace

How to knot the bottom of induction melting furnace

The thickness of the normal furnace bottom is about 200mm-280mm, and the sand is filled in two to three times to prevent uneven density everywhere during manual knotting, and the furnace lining after baking and sintering is not dense. Therefore, it is recommended that the thickness of the feed must be strictly controlled. Generally, the thickness of the sand filling is not more than 100mm/each time, and the furnace wall is controlled within 60mm. Multiple people are divided into shifts, 4-6 people per shift, and 30 minutes for each knot replacement. Rotate slowly around the furnace to change the position, with even force, so as not to cause uneven density.

When the knots at the bottom of the furnace reach the required height, the crucible mold can be placed by scraping it flat. In this regard, care should be taken to ensure that the crucible mold is concentric with the induction coil, adjusted vertically up and down, and the shape is as close as possible to the bottom of the furnace built. After adjusting the peripheral clearance to be equal, use three wooden wedges to clamp, and the middle lifting weight is pressed on to avoid the furnace wall. Displacement of quartz sand occurs when knotting.