- 23

- Nov

How to design the induction coil of the induction melting furnace?

How to design the induction coil of the induction melting furnace?

How to design the induction coil of the induction melting furnace?

The inductor is the heart of the entire furnace body. It not only directly affects the power absorption of the furnace body, but the rationality of its design and manufacturing quality also directly affect the service life of the furnace lining.

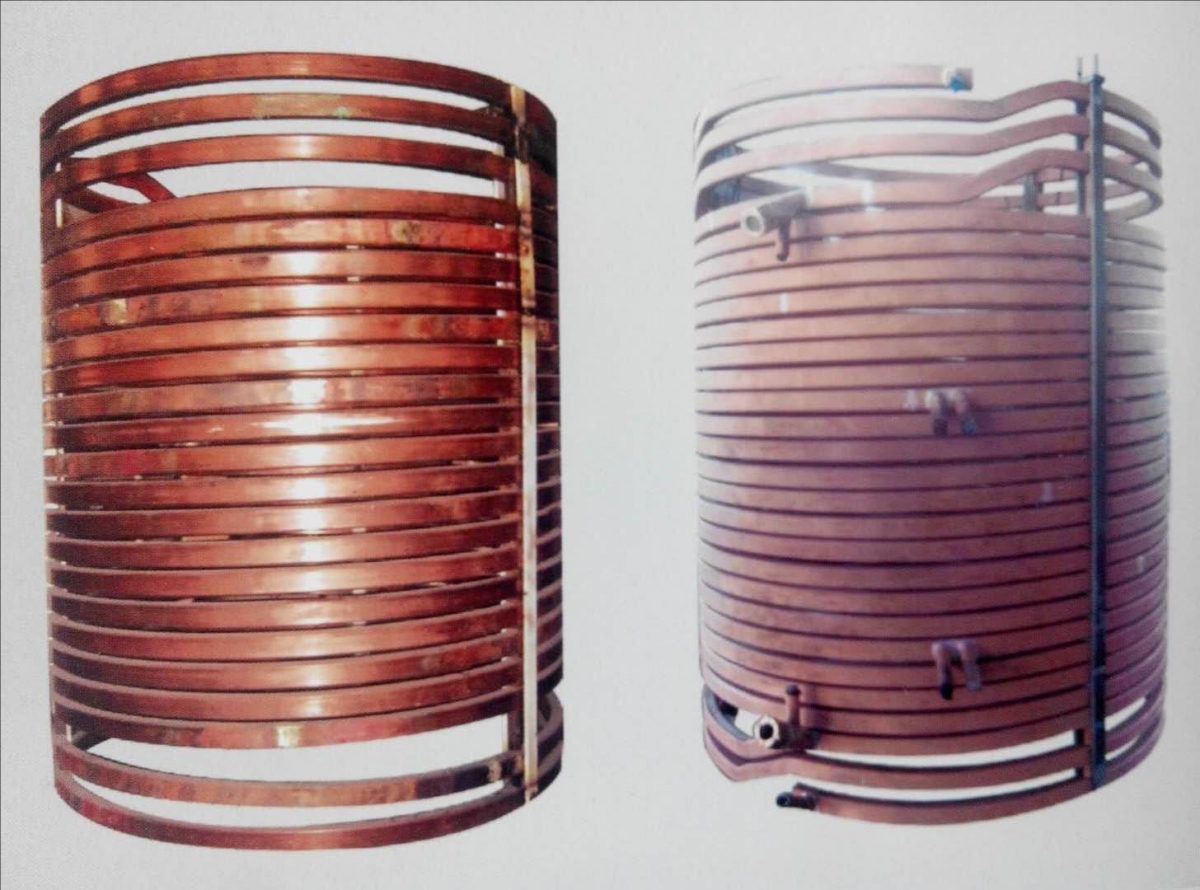

The coil of the smelting furnace is made of TU1 (purity of 99.9% electrolytic copper) and an extruded rectangular copper tube with a wall thickness of ≥6mm, which is wound on a special mold. It not only ensures the rigidity of the coil, but also has the largest conductive cross-section. Fix it on the 3240 insulation column with copper screws. The copper tube has high conductivity and high efficiency. When our company makes the inductor, the height and diameter of the molten iron in the furnace are relatively high. It is determined on the basis of computer optimization design analysis, and with reference to the use experience of similar equipment and foreign advanced furnace models. It has been verified by multiple tests and has the characteristics of reasonable structural design and high efficiency. The natural power factor of the equipment is improved, and the electrical efficiency is improved.

The coil material is selected according to the ISO431-1981 standard, which has the smallest copper loss and the highest electromagnetic conversion efficiency.

The induction coil adopts high temperature resistant, high pressure resistant insulating paint, the whole is dipped and dried in vacuum, and the insulation level reaches H level. The induction coil has undergone a 12kg/cm2 water pressure withstand test for 36 hours and a 7000V withstand voltage test before leaving the factory, and there will be absolutely no leakage of water.

The upper and lower parts of the induction coil are equipped with copper water cooling coils to ensure that the furnace lining is heated evenly. And there is a Faraday short-circuit ring to fully absorb the leakage magnetic flux at the upper and lower ends to prevent the furnace body from heating up. The sensor is connected with a large cross-section water-cooled cable with a side lead wire. The coil pressing device adopts stainless steel pull rod to pull up and down, which is easy to disassemble and replace, and it is convenient to replace the coil.