- 09

- Sep

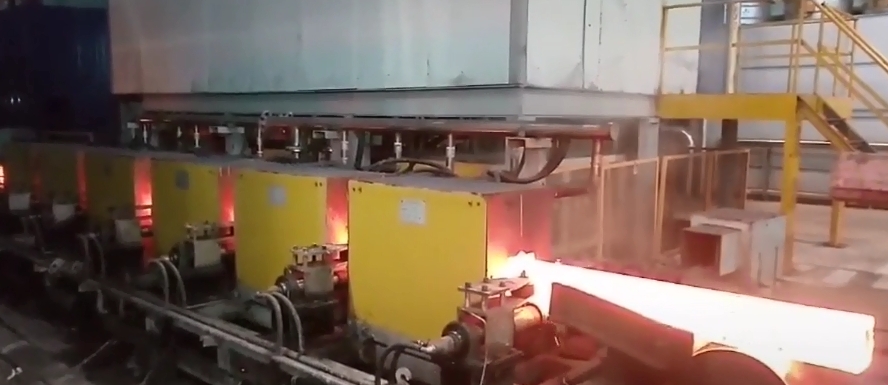

Billet induction heating furnace

Billet induction heating furnace

The billet induction heating furnace is a furnace that specializes in heating billets. It is mainly used to supplement and increase the temperature of the billet before rolling, or directly heat it to the rolling temperature. The complete set of billet induction heating furnace parameters are introduced as follows.

1. Billet induction heating furnace requirements:

1. Billet size: 100mm×100mm×6000mm

2. The weight of the billet is approximately: 78.5Kg/m

3. Initial temperature 800℃, rolling temperature 1200℃, supplementary temperature 400℃

4. Heating speed: 3.0m/min

5. The maximum curvature of the square billet before entering the furnace: ≤3mm/m

2. Design parameters of a complete set of billet induction heating furnace:

1. The total heating power of the slab intermediate frequency heating furnace is 2000Kw=1000Kw+800Kw+200Kw

2. The slab intermediate frequency heating furnace adopts one heating line, and the heating is divided into three zones. The total load of the slab intermediate frequency heating furnace is 2000Kw. The heating speed can meet 3.0m/min. The heating mode of this slab intermediate frequency heating furnace is longitudinal heating of the workpiece. There are three zones in the whole set of slab intermediate frequency heating furnace, namely the preheating zone, the heating zone and the heat preservation zone.

3. Three sets of intermediate frequency power supplies are: 1000Kw/800Hz, 800Kw/1500Hz, 200Kw/2500Hz

4. The mechanical part is composed of a storage platform, a feeding system, a discharging system, a water-cooled roller, a temperature measurement system, and a control system.