- 02

- Jun

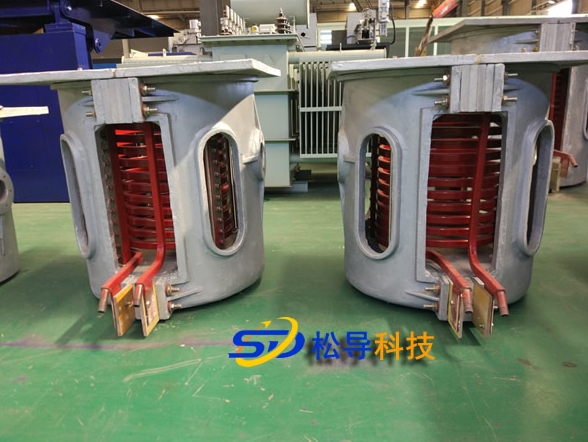

Introduction of mobile vacuum hood for induction melting furnace

Introduction of mobile vacuum hood for ڀڃڻ جي پگھلڻ واري فرنس

The dust collector of induction melting furnace is composed of shell, filter bag, ash hopper, ash discharge device, bracket and pulse ash cleaning system. When the dust-laden gas enters the dust collector from the air inlet, it first hits the inclined partition in the middle of the air inlet, and the airflow turns to flow into the ash hopper. At the same time, the airflow speed slows down. Due to gravity sedimentation, the coarse particles in the gas fall directly. Into the ash hopper, play a role in pre-collecting dust. The airflow entering the ash hopper then folds upwards and passes through the filter bag with a metal frame inside. The dust is trapped on the outer surface of the filter bag. The purified gas enters the clean room at the upper part of the filter bag chamber and is collected in the air outlet pipe for discharge. .

Features of Induction Melting Furnace Dust Collector

1. The dust collecting cover is used to collect dust, there is no dead corner, and the dust cleaning effect is better;

2. The use of advanced feeding equipment solves the problem that the flue gas is difficult to capture when feeding;

3. According to user needs, different structural combinations can be designed to achieve excellent dust removal effect;

The working principle of the dust collector of the induction melting furnace

The induction melting furnace dust collector is economical and practical, simple in structure, easy to install and easy to maintain. It is mainly used for dust collection at small dust points. The machine uses polyester cloth bags. The inlet temperature is about 120 degrees Celsius, and the dust removal effect can reach 99%. For special purposes, a temperature-resistant and corrosion-resistant filter bag dust collector can be provided.

The induction melting furnace flue gas capture system consists of a low-position mobile dust collecting hood, feeding equipment, tapping equipment and dust removal equipment. The low-position mobile dust collecting hood covers the operation platform and the tapping pit, so that the smelting production process of the induction melting furnace is all carried out in the low-position mobile dust collecting hood, which realizes the effective capture of the entire process of flue gas. When feeding, the feeding equipment is used for feeding, and the material is filled up several times according to the production needs, which solves the problem of difficult to capture flue gas during driving and feeding; when the steel is tapped, the induction melting furnace platform is flipped directly out to the tapping track flat car In the steel ladle, the tapping process is completed in the fume hood, which overcomes the partial leakage of flue gas during tapping of the partial dust collection hood.

Operating characteristics of dust collector for induction melting furnace

The air inlet of the dust removal equipment of the induction melting furnace is set on the ash hopper. After the airflow enters the ash hopper, it first hits the baffle at the end of the air inlet pipe. Its function is the same as the above principle. Each dust collection chamber is cleaned in turn according to a given time interval. Each dust collection chamber is equipped with a poppet valve. The poppet valve is closed during dust removal to cut off the filtered air flow through the dust collection chamber, and then the electromagnetic pulse valve opens , Spray water-free and oil-free high-pressure clean air into the filter bag to remove dust on the outer surface of the filter bag. The pulse blowing width and cleaning cycle of each dust collection chamber are automatically and continuously carried out by a dedicated cleaning degree controller.

The induction melting furnace flue gas capture system consists of a low-position mobile dust collecting hood, feeding equipment, tapping equipment and dust removal equipment. The low-position mobile dust collecting hood covers the operation platform and the tapping pit, so that the smelting production process of the induction melting furnace is all carried out in the low-position mobile dust collecting hood, which realizes the effective capture of the entire process of flue gas. When feeding, the feeding equipment is used for feeding, and the material is filled up several times according to the production needs, which solves the problem of difficult to capture the flue gas during feeding; when the steel is tapped, the induction melting furnace platform flips directly out to the tapping track flat car. In the ladle, the tapping process is completed in the fume hood, which overcomes the partial leakage of the flue gas during tapping of the partial dust hood.