- 01

- Oct

Kupisa blast chitofu cheki chidhinha

Kupisa blast chitofu cheki chidhinha

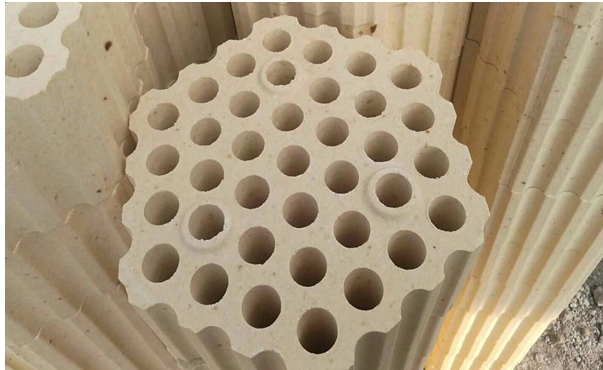

A. Iyo inotakura inopisa yeinopisa blast chitofu iporous checker zvidhinha. Iyo porous checker chidhinha parizvino inozivikanwa zvakanyanya uye inogamuchirwa neve indasitiri yekugadzira iron. Iyo ine simba rakasimba rekutsinhana kupisa, nzvimbo hombe yekuchengetera kupisa, kufefetedza mweya, uye yakaderera kuramba. Hunhu kupisa-kutakura kupisa muviri wekuchengetedza. …

B. Checker chidhinha imhando yezvidhina zvinokatyamadza zvinowanzo shandiswa mumoto unopisa. Kumusoro kwayo hakuna kuenzana, iine maburi akajeka mukati. Zvinoenderana nehunhu hwayo, inowanzo shandiswa yematanda cheki zvidhinha zvinonyanya: maburi manomwe, makomba 7, maburi makumi matatu nemasere, maburi makumi matatu nematatu, makumi matanhatu nemashanu. Zvinoenderana nezvakasiyana zvinoshandiswa, zvakapatsanurwa kuita zvidhinha zvevhu nevhu-alumina cheki zvidhinha.

| Grid dhayamita mm | Makomba manomwe

43 |

Makomba gumi nemapfumbamwe

Φ33 |

Makomba gumi nemapfumbamwe

Φ30 |

Makomba gumi nemapfumbamwe

Φ28 |

Makomba makumi matatu nemanomwe

Φ23 |

Makomba makumi matatu nemanomwe

Φ20 |

| Chikamu kudziyisa pamusoro m2 / m2 | 38.05 | 44.36 | 48.61 | 50.71 | 59.83 | 64.0 |

| Kurarama nzvimbo m2 / m2 | 0.409 | 0.366 | 0.365 | 0.355 | 0.344 | 0.320 |

| Kuchengetedza kupisa vhoriyamu m2 / m2 | 0.591 | 0.634 | 0.635 | 0.645 | 0.656 | 0.680 |

| Yakaenzana ukobvu mm | 31.07 | 28.60 | 26.14 | 25.44 | 21.93 | 21.25 |

C. Zvimiro:

Iyo ine huwandu hwakawanda hwejekerere gidhi maburi akaenzana kune epadivi nzvimbo, uye yekumisikidza protrusions uye yekumisikidza grooves pane maviri akafanana nzvimbo.

Kugadzikana kwakanaka kwevhoriyamu, yakanakisa tembiricha yepamusoro mutoro zvinokambaira kuita, kukwirira kwehuwandu uye pasi porosity. Yemazuva ano blast choto inopisa blast stoves kazhinji inotora checkered zvidhinha regenerator chimiro. Perforated checker zvidhinha inowedzera iyo yekudziya nzvimbo, inoderedza kudyiwa kwekutarisa zvidhinha, uye zvakanyanya kudzikisira kudyiwa kweanopokana zvinhu zveanopisa mafuroti zvitofu, nokudaro zvichideredza kudyara kweanopisa mabhuru stofu.

D. Kushanda:

Parizvino, zvidhina zvekutarisa zvinonyanya kushandiswa mukufutisa choto inopisa blast stoves uye marimi emoto. Checker zvidhinha zvinonyanya kushandiswa muiyo inogadzirisazve yeanopisa mafuru zvitofu. Zvidhinha zvine maburi eredhiyo zvakarongedzwa nenzira yakarongeka. Iyo yekumusoro neyakadzika kuburikidza nemakomba ezvitinha zvekutarisa inogona kubvumira gasi kupfuura. Zvinoenderana nehunyanzvi hunodiwa hwekupisa kwakasiyana nzvimbo, siliceous checker zvidhinha, ivhu zvidhinha, nezvimwe zvinowanzoshandiswa. Mune mamwe masitofu anopisa anopisa, zvidhinha zvealumumina, zvidhinha zvemullite, zvidhinha sillimanite, nezvimwewo zvinosarudzwa.

E. Basa rechitofu chemhepo inopisa kupisa mweya unotonhorera unotumirwa neanofuridza kuchoto chekupisa mumhepo inopisa, uyezve mweya unopisa unotumirwa kuchoto chekuputika kuburikidza nepombi yemhepo inopisa yekuita kwekupisa. Iyo yekufema yevira inopisa blast chitofu ine choto chinopisa nguva uye nemhepo yekupa nguva, uye iwo maviri ekushanda nguva anoshandurwa nguva nenguva. Munguva yekutsva kwechoto, iyo yakanyanya-tembiricha flue gasi mushure memoto inopfuura nepakati pemaburi ezvitinha zvekutarisa kweanopisa stove stove kuendesa kupisa kune cheki zvidhinha; panguva yekuwaniswa kwemhepo, mweya unotonhorera unobva kune unofuridza unopinda muchoto chinopisa uye unopiswa nezvidhinha mumhepo inopisa. Iyo inotumirwa kune iyo blast furna kuburikidza neanopisa mweya pombi.

F. Zviratidzo zvemuviri nemakemikari:

| purojekiti | Rondedzera |

| SiO2,% | ≥95 |

| Al2O3,% | ≤1 |

| Fe2O3,% | ≤1.5 |

| Kugadziriswa, ℃ | ≥1710 |

| Zviripachena porosity,% | ≤23 |

| Kuwanda kwehuwandu, g / cm3 | ≥1.9 |

| 0.2MPa mutoro unopfavisa kutanga tembiricha, ℃ | ≥1650 |

| Linear shanduko mwero yekudzorerazve, 1500 ℃ × 4h% | ± 0.2 |

| Chinokambaira zvazvingava,% | ≤0.2 |

| (0.2MPa, 1500 ℃, 20-50h) | |

| Residual quartz zvemukati% | ≤1.0 |