- 01

- Oct

Isitini sokuhlola isitofu esishisayo

Isitini sokuhlola isitofu esishisayo

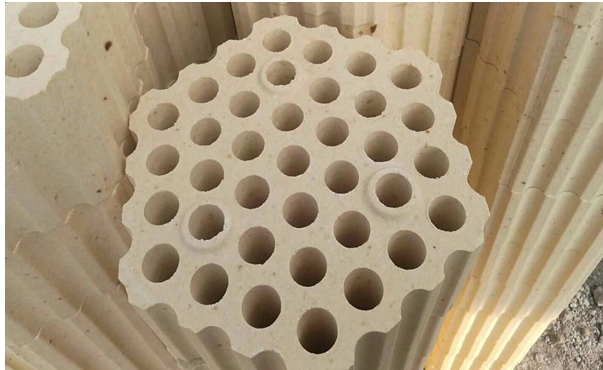

A. Okuphatha ukushisa kwesitofu esishisayo kuqhuma isitini esihlola ukungena komlilo. Isitini esinezihlahla ezinamaphasi njengamanje saziwa kabanzi futhi samukelwa imboni yomhlaba yokwenza insimbi. Inamandla okushintshanisa ukushisa okunamandla, indawo enkulu yokugcina ukushisa, umoya omncane obushelelezi, nokumelana okuphansi. Isici sokugcina ukushisa okuphethe ukushisa. …

Izitini ezihlola uhlobo oluthile lwezitini ezinenkani ezijwayele ukusetshenziselwa izitofu eziqhumayo. Ubuso bawo abalingani, bunemigodi ebonakalayo phakathi. Ngokwezici zayo zesakhiwo, izitini zamasheke ezivame ukusetshenziswa kakhulu ikakhulukazi: izimbobo eziyi-7, izimbobo eziyi-19, izimbobo ezingama-31, izimbobo ezingama-37, izimbobo ezingama-65. Ngokuya ngezinto ezehlukene ezisetshenzisiwe, ihlukaniswe ngezitini zokuhlola ubumba nezitini zokuhlola ama-high-alumina.

| Ububanzi begridi mm | Izimbobo eziyisikhombisa

43 |

Izimbobo eziyishumi nesishiyagalolunye

Φ33 |

Izimbobo eziyishumi nesishiyagalolunye

Φ30 |

Izimbobo eziyishumi nesishiyagalolunye

Φ28 |

Izimbobo ezingamashumi amathathu nesikhombisa

Φ23 |

Izimbobo ezingamashumi amathathu nesikhombisa

Φ20 |

| Iyunithi yokushisa ebusweni m2 / m2 | 38.05 | 44.36 | 48.61 | 50.71 | 59.83 | 64.0 |

| Indawo yokuhlala m2 / m2 | 0.409 | 0.366 | 0.365 | 0.355 | 0.344 | 0.320 |

| Umthamo wesitoreji sokushisa m2 / m2 | 0.591 | 0.634 | 0.635 | 0.645 | 0.656 | 0.680 |

| Ubukhulu obulinganayo mm | 31.07 | 28.60 | 26.14 | 25.44 | 21.93 | 21.25 |

C. Izici:

Inobuningi bezimbobo zegridi ezisobala ezihambisana nezindawo eziseceleni, nokubeka ama-protrusions nokubeka ama-groove ezindaweni ezimbili ezifanayo.

Ukuzinza kwevolumu enhle, ukusebenza okuhle kokushisa okuphezulu kokushisa, ukuminyana okuphezulu kanye ne-porosity ephansi. Izitofu zanamuhla zokuqhuma kwesitofu esishisayo zivame ukwamukela isakhiwo sokuvuselela izitini ezi-checkered. Izitini zokuhlola ezenziwe ngopende zandisa indawo yokushisa, zinciphisa ukusetshenziswa kwezitini zokuhlola, futhi zinciphisa kakhulu ukusetshenziswa kwezinto zokwakha izitofu ezishisayo, ngaleyo ndlela kuncishiswe utshalomali lwezitofu ezishisayo.

Isicelo:

Njengamanje, izitini zokuhlola zisetshenziswa kakhulu ezithandweni zomlilo ezishisayo nasezitofini zomlilo. Izitini zama-Checker zisetshenziswa kakhulu ekuvuseleleni izitofu eziqhumayo. Izitini zokuhlola ezinemigodi yama-lattice zihlelwe ngendlela ehlelekile. Izimbobo ezingenhla nezingaphansi zezitini ezihlola zingavumela igesi ukuthi idlule. Ngokuya ngezidingo zobuchwepheshe zezindawo ezinamazinga okushisa ahlukahlukene, izitini zokuhlola ezinosilika, izitini zobumba, njll. Kwezinye izitofu eziqhumayo, izitini eziphakeme ze-alumina, izitini ze-mullite, izitini ze-sillimanite, njll.

E. Umsebenzi wesitofu somoya oshisayo ukufudumeza umoya obandayo othunywe oshaya esithandweni sokuqhuma ungene emoyeni oshisayo, bese umoya oshisayo uthunyelwa esithandweni sokuqhuma ngepayipi lomoya elishisayo lokuphendula ngomlilo. Isithando sokuqhuma esithandweni esishisayo sinesikhathi sokushisa kwesithando somlilo nesikhathi sokuphakelwa komoya, futhi izikhathi ezimbili zokusebenza ziyashintshaniswa ngezikhathi ezithile. Esikhathini somlilo esivuthayo, igesi ephezulu yokushisa okushisa ngemuva kokushisa komlilo idlula emigodini yezitini zokuhlola zesitofu esishisayo sokudlulisa ukushisa ezitinini zokuhlola; ngesikhathi sokuphakelwa komoya, umoya obandayo ovela ku-blower ungena esitofini esishisayo futhi ushiswa yizitini ezihlola emoyeni oshisayo. Ithunyelwa esithandweni sokuqhuma ngepayipi lomoya oshisayo.

Izinkomba zomzimba nezamakhemikhali:

| project | Bukela ku |

| I-SiO2,% | ≥95 |

| I-Al2O3,% | ≤1 |

| I-Fe2O3,% | ≤1.5 |

| Ukuphindisela emuva, ℃ | ≥1710 |

| I-porosity ebonakalayo,% | ≤23 |

| Ubuningi besibalo, g / cm3 | ≥1.9 |

| Ukushisa kokuqala okungu-0.2MPa, ℃ | ≥1650 |

| Ukuthuthukiswa kwesilinganiso sokushisa kabusha, 1500 ℃ × 4h% | ± 0.2 |

| Izinga lokungena,% | ≤0.2 |

| (0.2MPa, 1500 ℃, 20-50h) | |

| Okuqukethwe kwe-quartz okusele% | ≤1.0 |