- 17

- May

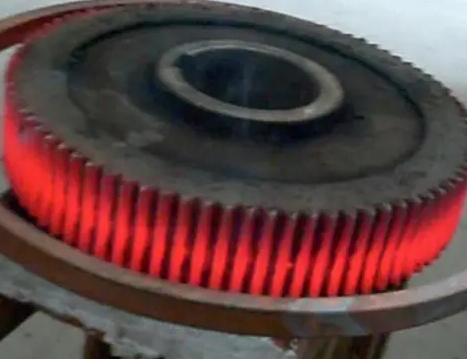

Advantages of gear laser quenching process

Faa’iidooyinka habka deminta laysarka marsho

1. Special advantages: After laser quenching, the gears have hard tooth surfaces and soft roots. The tooth surfaces are wear-resistant and at the same time ensure the overall mechanical properties of the gears, and are more in line with the use requirements of the gears.

2. High wear resistance: The gears treated by laser quenching have high hardness, refined metallographic structure and better wear resistance than traditional quenching process. Laser quenching produces compressive stress in the tissue and improves the fatigue resistance of the gear.

3. Small deformation: The deformation of the tooth profile of the laser quenched gear is within 0.01mm, without cracks, and the original surface roughness can be maintained. The laser quenched gear can be directly installed and used.

4. Short production cycle: Due to the small deformation of laser quenching, there is generally no need to re-grind the teeth, simplifying the production process, improving production efficiency and reducing production costs.

5. Expand the range of gear material selection: low-priced steel grades can be used to manufacture gears, and the hardness of the tooth surface can be improved by laser quenching to ensure the use requirements.