- 06

- Sep

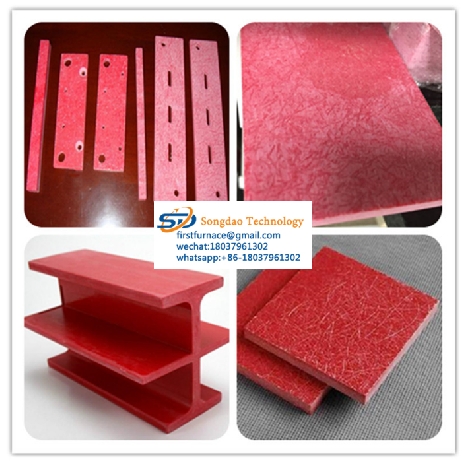

Looxa maro galaas Epoxy ah oo guduud ah oo loogu talagalay jillaab wareegga wareegga

Looxa maro galaas Epoxy ah oo guduud ah oo loogu talagalay jillaab wareegga wareegga

GPO-3 board insulation waa qalab dahaar leh oo qaab-dhismeed ka samaysan oo ka samaysan fiber-galaas oo aan lahayn alkali oo dareemay loox lagu dahaaray dhejin cusbi polyester oo aan la buuxin oo lagu daray waxyaalo u dhigma iyada oo loo marayo cadaadis kulul. Waxaa loola jeedaa maaddada gogolka ah ee polyester -ka aan la buuxin, oo loo isticmaalo ujeeddooyin farsamo iyo koronto. Waxay leedahay waxqabad koronto oo wanaagsan oo ka hooseeya huurka sare, waxqabad farsamo oo wanaagsan heerkulka dhexdhexaadka ah, dib -u -dhaca ololka, iska caabinta arc iyo iska -caabbinta raadadka dillaaca.

A. Hordhac alaab

GPO-3 board insulation waa qalab dahaar-qaabeeya oo saxan oo adag oo ka samaysan fiber galaas aan lahayn alkali oo la dareemay guddi lagu dhajiyay koollada polyester-ka oo aan la buuxin oo lagu daray waxyaalo u dhigma iyada oo loo marayo cadaadinta kulul. Waxaa loola jeedaa walxaha gogosha caagad polyester -ka oo aan la buuxin si loogu isticmaalo farsamada iyo korontada. Waxay leedahay waxqabad koronto oo wanaagsan oo ka hooseeya huurka sare, waxqabad farsamo oo wanaagsan heerkulka dhexdhexaadka ah, dib -u -dhaca ololka, iska caabinta arc iyo iska -caabbinta raadadka dillaaca.

Tilmaamaha: 1000* 2000* (dhumucdiisuna tahay 2-30) mm, 1020* 1220* (dhumucda 0.8-10) mm, 1000* 1200* (dhumucda 3-50) mm, 1200* 2500* (dhumucdiisuna tahay 3-45) mm

Midabka: caddaan, bunni-cas, iwm

Dahaarka korontada: Dhammaan dahaarka dahaarka ee korontadu waa dabiiciyeyaal tayo sare leh. Halkan, marka loo eego astaamaha darajada, iyadoo la adeegsanayo waxqabadkeeda gaarka ah, waxaa si weyn loogu adeegsadaa injineernimada korontada xagga farsamada injineernimada.

B. Product characteristics

1. Wax-qabadka dab-damiska: Fasallada 1580 iyo UTR waa UL-lagu qiimeeyay V-0. Darajada UTR waa halogen-free, nidaamkuna wuxuu soo saaraa qiiq aad u yar iyo qiiqa sunta ah marka uu dab qabsado.

2. Mechanical strength: The high-strength glass fiber reinforced polyester laminate will not be crushed. Due to its isolation properties, rigid laminates provide structural support. Flexible laminates can be used for applications with small bends of 19mm in diameter.

3. Iska -caabbinta kulaylka: Guryaha ilaalinta iyo xasilloonida cabbirka ee ay bixiyaan maaddada dahaarka leh inta lagu guda jiro hawsha kululaynta. Laamiyayaashan waxay leeyihiin qiimeynta heerkulka UL ee elektaroonigga ah 120-210 ° C iyo 130-210 ° C ee farsamooyinka.

4. Way fududahay in la qaabeeyo: Qalabkan si fudud ayaa loo farsamayn karaa loona qaabayn karaa iyadoo la isticmaalayo qalabka hawlgalka biraha ee caadiga ah. Waa la feeri karaa, la qodi karaa, la farsamayn karaa, waa la jari karaa oo ciid baa la gelin karaa. Fasalka UTR wuxuu caan ku yahay xarumaha mashiinnada si loogu fududeeyo wax-soo-saarka xawaaraha sare iyo wax-ka-beddelka. Fasalka 1580 si nadiif ah oo dhaqso leh ayuu feerayaa.

5. It is inferior products that smoke and dust appear. The adhesion of the product is very good, and the material itself is environmentally friendly and does not produce smoke or dust.

6. Waxaa la soo saaraa gaas sumaysan. Badeecadaha liita guud ahaan waxay adeegsadaan dab -dejiyayaasha ololka si ay u gaaraan saamaynta dab -damiyaha, sidaa darteed waxaa jira gaas sun ah oo aad u xun marka la gubo. Isbeddelka dab -damiyaha, waxqabadka alaabta ayaa sidoo kale la dhimay. Looma isticmaali karo deegaan ay dadku xiriir la leeyihiin iyo jawi kulul.

7. Kala -saaridda gubashada. Sababtoo ah qaab-dhismeedka aan caadiga ahayn ee sariirta dhalada galaaska, xiisadda farsamada ee GPO-3 ayaa ka timaada gudaha, iyo kala-soocidda gudaha ma dhici doonto inta lagu jiro carbonization heerkulka sare leh. Haddii ay jirto kala -saarid inta lagu jiro gubashada, waa badeecad tayadeedu liidato.

8. Awoodda adkeysiga: dhumucda 3mm ≥25KV, dhumucda 4mm ≥33KV, dhumucda 5-6mm ≥42KV, dhumucda 7-10mm ≥48KV, dhumucda 10mm ≥60KV.

C. Product application

1. Codsiga jejebiyeyaasha wareegga: Jeexayaasha jaad -gooye nooca: Qaababka badbaadada, xidhayaasha badbaadada, meeleeyaha, meeleeyaha wejiga, iwm.

2. Applications in molded case circuit breakers: phase spacers, arc extinguishing chambers, etc.

3. Codsiga matoorrada: qaybaha armature -ka mootada, taargooyinka daboolka dhaqaajiya, daboollada jeexjeexyada, makiinadaha go’an, makiinadaha dhuuban, kuwa haysta burushka kaarboon, iwm.

4. Codsiga ku -beddelashada: dhammaadka hore, dhammaadka dambe, dhammaadka sare, dhammaadka hoose, kala -wareegga wajiga, iwm ee nidaamka qaybinta. Araajida kale: qaybaha qaabdhismeedka u adkaysta arc.

D. Xuduudaha farsamada alaabta

| Waxyaabaha tijaabada ah | unit | Tilmaamo farsamo

GPO-3(A) I GPO-3(B) |

Hababka Tijaabada | |||

| 1 | dibadda | Dusha siman, goobooyin ma leh, dildilaacyo ma leh

Midho, oo leh badarka fiber |

Baadhitaan muuqaal ah | |||

| 2 | cufnaanta | g / cm3 | 1.75-1.90 | 1.75-1.90 | iso 1183-1:

2004Xeerka Difaaca A) GB / T 1033.1-2008 |

|

| 3 | Nuujinta biyaha | % | <0.25 | ISO 62: 2008

GB / T 1033-2008 |

||

| 4 | Xoog qumman oo toosan | caadiga ah | MPA | > 130 | > 110 | IS0178: 2001

GBfT 9341 -2000 |

| 130 ° C | > 90 | > 80 | ||||

| 5 | Lakabka toosan ilaa moolalka qumman | MPA | > 1.0 x 104 | > 0.9 x 104 | ||

| 6 | Awoodda saamaynta ee lakabka tooska ah ayaa si fudud loo taageeray (ma jirto meel bannaan) | KJ / m2 | > 90 | > 70 | 150179-1: 2000

GB / T 1043.1-2008 |

|

| 7 | Vertical layer compression strength | MPA | > 180 | > 150 | ISO 604: 2002 | |

| 8 | Heerkulka dhalanrog kulaylka (TJ.8) | ° C | > 240 | > 200 | ISO 75-2 : 2003

GBfT 1634.2-2004 |

|

| 9 | caabin ningax | caadiga ah | Ω | > 1.0x 1013 | > 1.0x 1012 | I EC 60167: 1964

GBfT 10064-2006 |

| Ka dib markii 24h biyo lagu qooyay | > 1.0x 1012 | > 1.0x 1010 | ||||

| 10 | Jihada lakabka toosan xoogga korontada | Kv/mm | > 13.0 | > 12.0 | I EC 60243-1:1998

GB 1408.2-2006 |

|

| 11 | Isbarbar dhigga jihada xoogga burburka | Kv | > 80 | > 70 | ||

| 12 | Cilladda luminta Dielectric | IEC 60250: 1969

GB 1409-2006 |

||||

| 13 | Ogolaanshaha qaraabada | |||||

| 14 | Diidmada qaansada | s | > 180 | > 180 | IEC 61621: 1997

GB / T 1411-2002 |

|

| 15 | Tusmada Raadinta Resistance Index CTI | V | > 600 | > 600 | IEC 60112: 1979

GB / T 4207-2003 |

|

| 16 | Gubashada | fasalka | V-0 | V-1 、 V-2 | IEC 60695-11-10:

2003 UL94 |

|

| 17 | Long-term heat resistance humidity index | 155 | 130 | IEC 60216-1: 2001

GB / T 11026.1-2003 |

||

E. Sawirada alaabta

Looxa maro galaas Epoxy ah oo guduud ah oo loogu talagalay jillaab wareegga wareegga