- 06

- Sep

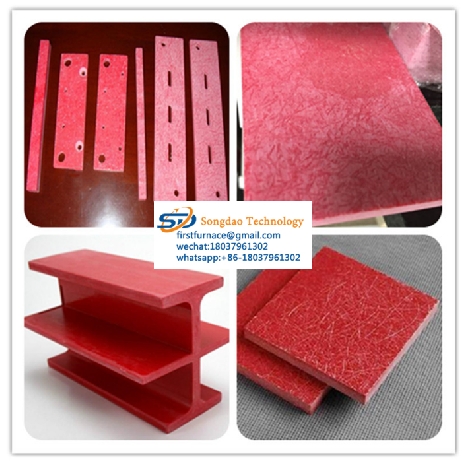

Epoxy glass cloth board red for frame type circuit breaker

Epoxy glass cloth board red for frame type circuit breaker

GPO-3 insulation board is a rigid board-shaped insulation material made of alkali-free glass fiber felt board impregnated with unsaturated polyester resin paste and added with corresponding additives through hot pressing. Refers to the unsaturated polyester fiberglass mat material, used for mechanical and electrical purposes. It has good electrical performance under high humidity, good mechanical performance under medium temperature, flame retardancy, arc resistance and resistance to leakage traces.

A. Product introduction

GPO-3 insulation board is a rigid plate-shaped insulation material made of alkali-free glass fiber felt board impregnated with unsaturated polyester resin paste and added with corresponding additives through hot pressing. Refers to the unsaturated polyester fiberglass mat material for mechanical and electrical use. It has good electrical performance under high humidity, good mechanical performance under medium temperature, flame retardancy, arc resistance and resistance to leakage traces.

Specifications: 1000*2000* (thickness 2-30) mm, 1020*1220* (thickness 0.8-10) mm, 1000*1200* (thickness 3-50) mm, 1200*2500* (thickness 3-45) mm

Color: white, brown-red, etc. (colors can be customized for large quantities)

Electrical insulation: All electrical insulation laminates are inherently high-quality insulators. Here, according to the grade characteristics, using its special performance, it is widely used in electrical engineering in the field of engineering technology.

B. Product characteristics

1. Flame retardant performance: Grades 1580 and UTR are UL-rated V-0. Grade UTR is halogen-free, and the system emits very little smoke and toxic smoke when it catches fire.

2. Mechanical strength: The high-strength glass fiber reinforced polyester laminate will not be crushed. Due to its isolation properties, rigid laminates provide structural support. Flexible laminates can be used for applications with small bends of 19mm in diameter.

3. Heat resistance: The protective properties and dimensional stability provided by the laminated material during the heating process. These laminates have UL temperature ratings in the 120-210°C electronic and 130-210°C mechanical ranges.

4. Easy to shape: These materials can be easily processed and shaped using standard metal operating equipment. It can be punched, drilled, machined, cut and sanded. Grade UTR is well-known in machining centers for its ease of high-speed production and molding. Grade 1580 punches cleanly and quickly.

5. It is inferior products that smoke and dust appear. The adhesion of the product is very good, and the material itself is environmentally friendly and does not produce smoke or dust.

6. Poisonous gas is produced. Inferior products generally use flame retardants to achieve the flame retardant effect, so there is a pungent poisonous gas when burned. With the volatilization of the flame retardant, the performance of the product is also reduced. It cannot be used in an environment where people are in contact with it and in a hot environment.

7. Burning stratification. Due to the irregular structure of the glass fiber mat, the mechanical tension of GPO-3 comes from the inside, and internal stratification will not occur during high-temperature carbonization. If there is stratification during combustion, it is a poor quality product.

8. Withstand voltage: 3mm thickness ≥25KV, 4mm thickness ≥33KV, 5-6mm thickness ≥42KV, 7-10mm thickness ≥48KV, 10mm thickness ≥60KV.

C. Product application

1. Application in circuit breakers: Frame type circuit breakers: safety shutters, safety shutters, spacers, phase spacers, etc.

2. Applications in molded case circuit breakers: phase spacers, arc extinguishing chambers, etc.

3. Application in motors: motor armature parts, movable cover plates, slot wedge stators, fixed washers, thin washers, carbon brush holders, etc.

4. Application in switchgear: front end, back end, upper end, bottom end, phase spacer, etc. in the partition system. Other applications: arc-resistant structural parts.

D. Product technical parameters

| Test items | unit | Technical index

GPO-3(A) I GPO-3(B) |

Test Methods | |||

| 1 | Exterior | Smooth surface, no bubbles, no cracks

Grain, with fiber grain |

Visual inspection | |||

| 2 | density | g/cm3 | 1.75-1.90 | 1.75-1.90 | iso 1183-1:

2004Defense law A) GB/T 1033.1-2008 |

|

| 3 | Water absorption | % | < 0.25 | <0.3 | ISO 62: 2008

GB/T 1033-2008 |

|

| 4 | Vertical dome strength | normal | Mpa | >130 | >110 | IS0178: 2001

GBfT 9341 -2000 |

| 130°C | >90 | >80 | ||||

| 5 | Vertical layer to dome modulus | Mpa | >1.0 x 104 | >0.9 x 104 | ||

| 6 | Impact strength of vertical layered simply supported beam (no gap) | KJ/m2 | >90 | >70 | 150179-1:2000

GB/T 1043.1-2008 |

|

| 7 | Vertical layer compression strength | Mpa | >180 | >150 | ISO 604: 2002 | |

| 8 | Heat distortion temperature(TJ.8) | °C | >240 | >200 | ISO 75-2 : 2003

GBfT 1634.2-2004 |

|

| 9 | Insulation resistance | normal | Ω | >1.0x 1013 | >1.0x 1012 | I EC 60167:1964

GBfT 10064-2006 |

| After 24h soaking in water | >1.0x 1012 | >1.0x 1010 | ||||

| 10 | Vertical layer direction electric strength | Kv/mm | >13.0 | >12.0 | I EC 60243-1:1998

GB 1408.2-2006 |

|

| 11 | Parallel layer direction breakdown strength | Kv | >80 | >70 | ||

| 12 | Dielectric loss factor | <0.015 | <0.015 | IEC 60250:1969

GB 1409-2006 |

||

| 13 | Relative permittivity | <4.5 | <4.8 | |||

| 14 | Arc resistance | s | >180 | >180 | IEC 61621:1997

GB/T 1411-2002 |

|

| 15 | Tracking Resistance Index CTI | V | > 600 | >600 | IEC 60112: 1979

GB/T 4207-2003 |

|

| 16 | Combustibility | class | V-0 | V-1 、 V-2 | IEC 60695-11-10:

2003 UL94 |

|

| 17 | Long-term heat resistance humidity index | 155 | 130 | IEC 60216-1:2001

GB/T 11026.1-2003 |

||

E. Product pictures

Epoxy glass cloth board red for frame type circuit breaker