- 06

- Sep

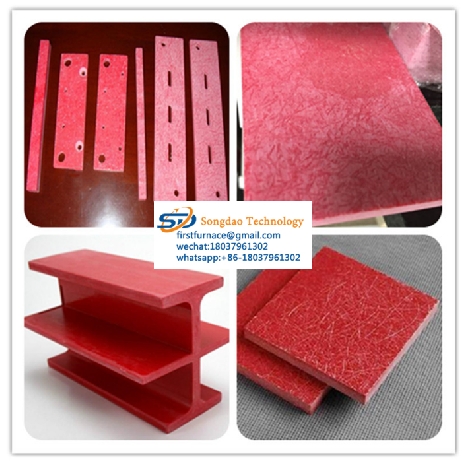

Boto ea lesela la epoxy e khubelu bakeng sa sekhahla sa mofuta oa potoloho

Boto ea lesela la epoxy e khubelu bakeng sa sekhahla sa mofuta oa potoloho

Boto ea ho kenya lintho tsa GPO-3 ke sesebelisoa se thata sa sebopeho sa boto se entsoeng ka khalase e se nang alkali e nang le khalase e utloiloeng e kentsoe boto ea polyester lehoakhoa la unsaturated mme e ekelitsoe ka li-additives tse tsamaellanang ka ho tobetsa khatello e chesang. E bua ka lintho tse sa sebelisoeng tsa polyester fiberglass mat mat, tse sebelisetsoang ho etsa mechini le motlakase. E na le ts’ebetso e ntle ea motlakase tlasa mongobo o phahameng, ts’ebetso e ntle ea mochini tlasa mocheso o mahareng, ts’ireletso ea lelakabe, ho hanyetsa arc le ho hanela mesaletsa ea ho dutla.

Kenyelletso ea sehlahisoa

Boto ea ho koala ea GPO-3 ke sesebelisoa se thata se bopehileng joaloka poleiti se entsoeng ka khalase e se nang alkali e nang le khalase e utloiloeng e kentsoe boto e nang le lehoakhoa la polyester le sa kopantsoeng mme e ekelitsoe ka li-additives tse tsamaellanang ka ho tobetsa khatello e chesang. E bua ka lisebelisoa tsa moseme tsa polyester fiberglass tse sa sebelisoeng bakeng sa ts’ebeliso ea mochini le motlakase. E na le ts’ebetso e ntle ea motlakase tlasa mongobo o phahameng, ts’ebetso e ntle ea mochini tlasa mocheso o mahareng, ts’ireletso ea lelakabe, ho hanyetsa arc le ho hanela mesaletsa ea ho dutla.

Tobileng: 1000 * 2000 * (botenya 2-30) limilimithara, 1020 * 1220 * (botenya 0.8-10) limilimithara, 1000 * 1200 * (botenya 3-50) limilimithara, 1200 * 2500 * (botenya 3-45) limilimithara

Mmala: o mosoeu, o mofubelu bo bofubelu, jj (mebala e ka hlophisoa ka bongata)

Lisebelisoa tsa motlakase Mona, ho latela litšobotsi tsa sehlopha, ho sebelisa ts’ebetso ea eona e ikhethang, e sebelisoa haholo ho boenjineri ba motlakase lefapheng la mahlale a boenjineri.

B. Product characteristics

1. Ts’ebetso ea lelakabe e sa sebetseng: Mephato ea 1580 le UTR li lekantsoe ka UL-V-0. Kereiti ea UTR ha e na halogen, ‘me sistimi e ntša mosi o monyane haholo le mosi o chefo ha e cha.

2. Matla a mechini: Matla a phahameng a khalase ea fiber ea polyester laminate e ke ke ea silakanngoa. Ka lebaka la thepa ea eona ea ho itšehla thajana, li-laminate tse thata li fana ka ts’ehetso ea sebopeho. Li-laminate tse tenyetsehang li ka sebelisoa bakeng sa lits’ebetso tse nang le likhahla tse nyane tsa 19mm bophara.

3. Ho hanyetsa mocheso: Thepa e sirelletsang le botsitso ba tlhakore e fanoeng ke lisebelisoa tse laminated nakong ea ho futhumatsa. Li-laminate tsena li na le litekanyetso tsa mocheso oa UL mefuteng ea 120-210 ° C ea elektroniki le 130-210 ° C.

4. E bonolo ho bopa: Lisebelisoa tsena li ka sebetsoa habonolo le ho bōptjoa ho sebelisoa lisebelisoa tse tloaelehileng tsa ts’ebetso ea tšepe. E ka phunyeletsoa, ea phunngoa, ea sebetsoa ka mechini, ea seoa le ea lehlabathe. Kereiti ea UTR e tsebahala litsing tsa machining bakeng sa boiketlo ba tlhahiso le lebelo le phahameng haholo. Kereiti ea 1580 e phunya hantle le ka potlako.

5. Ke lihlahisoa tse tlase tse hlahisoang ke mosi le lerōle. Khomarelo ea sehlahisoa e ntle haholo, ‘me thepa ka boeona e mosa tikolohong ebile ha e hlahise mosi kapa lerōle.

6. Ho hlahisoa khase e chefo. Lihlahisoa tse tlase hangata li sebelisa malakabe a lelakabe ho fihlela sephetho sa lelakabe, ka hona ho na le khase e chefo e chefo ha e chesoa. Ka volatilization ea retardant ea lelakabe, ts’ebetso ea sehlahisoa le eona ea fokotseha. E ke ke ea sebelisoa tikolohong eo batho ba kopanang le eona le tikolohong e chesang.

7. Ho chesa stratification. Ka lebaka la sebopeho se sa tloaelehang sa mochini oa khalase ea fiber, tsitsipano ea mochini oa GPO-3 e tsoa kahare, ‘me stratification ea kahare e ke ke ea etsahala nakong ea mocheso o phahameng oa mocheso. Haeba ho na le stratification nakong ea mollo, ke sehlahisoa sa boleng bo tlase.

8. mamella gagamalo: 3mm botenya ≥25KV, 4mm botenya ≥33KV, 5-6mm botenya ≥42KV, 7-10mm botenya ≥48KV, 10mm botenya ≥60KV.

Ts’ebeliso ea sehlahisoa

Kopo ho li-breaker tsa potoloho

Likopo ho li-breaker tsa linyeoe tse bōpiloeng: li-spacers tsa phase, likamore tsa ho tima tsa arc, jj.

3.Kopo ea likoloi: likarolo tsa likoloi, likarolo tsa sekoaelo tse tsamaeang, li-slot wedge stators, li-washer tse tsitsitseng, li-washer tse tšesaane, lipeipi tsa kh’habone, jj.

4.Kopo ea switchgear: pheletsong e ka pele, qetellong ea morao, qetellong e holimo, pheletsong e tlase, mohatong oa mohato, jj ho sistimi ea likarolo. Likopo tse ling: likarolo tsa sebopeho sa arc.

D. Litekanyetso tsa mahlale a lihlahisoa

| Lintho tsa liteko | unit | Index ea botekgeniki

GPO-3(A) I GPO-3(B) |

Mekhoa ea Teko | |||

| 1 | Ka ntle | Bokaholimo bo boreleli, ha ho na bubble, ha ho mapetso

Lihlahisoa-thollo, le lijo-thollo tsa faeba |

Tlhahlobo e bonoang | |||

| 2 | bongata ba tsona | g / cm3 | 1.75-1.90 | 1.75-1.90 | iso 1183-1:

2004 Molao oa ts’ireletso A) GB / T 1033.1-2008 |

|

| 3 | Ho kenngoa ha metsi | % | <0.25 | ISO 62: 2008

GB / T 1033-2008 |

||

| 4 | Vertical Dome matla | E tloaelehileng | Mpa | > 130 | > 110 | IS0178: 2001

GBfT 9341 -2000 |

| 130 ° C | > 90 | > 80 | ||||

| 5 | Lathe lera ho dome modulus | Mpa | > 1.0 x 104 | > 0.9 x 104 | ||

| 6 | Tshusumetso matla a paatsepama mekhahlelo feela tšehelitsoe toloki (ha ho na lekhalo) | KJ / m2 | > 90 | > 70 | 150179-1: 2000

GB / T 1043.1-2008 |

|

| 7 | Vertical lera compression matla | Mpa | > 180 | > 150 | ISO 604: 2002 | |

| 8 | Mocheso o khopamisang mocheso (TJ.8) | ° C | > 240 | > 200 | ISO 75-2: 2003

EA-1634.2-2004 |

|

| 9 | Ho thibela ho thibela | E tloaelehileng | Ω | > 1.0x 1013 | > 1.0x 1012 | I EC 60167: 1964

EA-10064-2006 |

| Kamora 24h ho inela ka metsing | > 1.0x 1012 | > 1.0x 1010 | ||||

| 10 | Lathe lera tataiso matla a motlakase | Kv / limilimithara | > 13.0 | > 12.0 | I EC 60243-1:1998

GB 1408.2-2006 |

|

| 11 | Matla a tšoanang a lera la ho senyeha | Kv | > 80 | > 70 | ||

| 12 | Tahlehelo ea dielectric | IEC 60250: 1969

GB 1409-2006 |

||||

| 13 | Tumello e amanang | |||||

| 14 | Khanyetso ea Arc | s | > 180 | > 180 | IEC 61621: 1997

GB / T 1411-2002 |

|

| 15 | Tracking Resistance Index CTI | V | > 600 | > 600 | IEC 60112: 1979

GB / T 4207-2003 |

|

| 16 | Ho chesa | sehlopha sa | V-0 | V-1, V-2 | IEC 60695-11-10:

2003 UL94 |

|

| 17 | Long-term heat resistance humidity index | 155 | 130 | IEC 60216-1: 2001

GB / T 11026.1-2003 |

||

Litšoantšo tsa sehlahisoa

Boto ea lesela la epoxy e khubelu bakeng sa sekhahla sa mofuta oa potoloho