- 23

- Sep

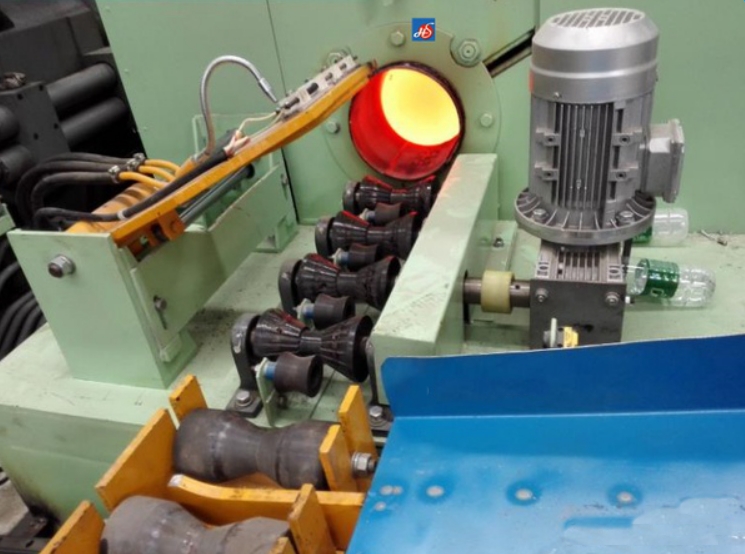

Steel rod heating furnace

Steel rod heating furnace

1. Technical parameters of steel rod heating furnace:

1. Heating material of steel rod heating furnace: carbon steel, alloy steel, stainless steel, titanium alloy steel, alloy aluminum, alloy copper and other metal materials

2. Heating rod material specification of steel rod heating furnace: round steel diameter range: 25mm—450mm; length range: 50mm-12000mm

3. Heating power of steel rod heating furnace: 50KW-20000KW

4. Heating efficiency of steel rod heating furnace: 0.2-50 tons per hour.

5. The elastic adjustable pressure roller of the steel rod heating furnace: the steel rods of different diameters can be fed at a uniform speed. The roller table and the pressure roller between the furnace bodies are made of 304 non-magnetic stainless steel and water-cooled.

6. Energy consumption of steel bar heating furnace: heating to 930℃~1050℃, power consumption 260~300℃.

7. Infrared temperature measurement of steel rod heating furnace: an infrared temperature measurement device is installed at the discharge end to make the temperature of the steel rod heating consistent.

8. The steel rod heating furnace provides a remote operation console with a touch screen or an industrial computer system according to your needs.

9. The steel rod heating furnace has a human-machine interface touch screen PLC automatic intelligent control system, and highly user-friendly operation instructions

2. Steel rod heating furnace

Steel rod heating furnace process: The steel rod heating furnace is easy to operate. The American Leitai two-hand infrared thermometer device is installed at the steel rod heating furnace mouth, which can monitor and control the temperature of the bar during the entire processing process and control the production cycle. When the steel rod heating furnace starts to feed, the infrared thermometer will leave the bar material, rotate an angle, and then the push rod will push the bar material into the induction heater. The next roller will transfer the round steel to the end of the roller. Then the feeder transfers the steel bar to the discharge rack. During the launch, the thruster will return to normal, and the next shot will be transferred to the feeder rack. At the same time, the infrared thermometer will return to the measuring position and touch the head of the club. Then one feeding and discharging ends. Usually, the steel rod heating furnace will be equipped with a holding furnace to make the round steel evenly heated.

3. Steel rod heating furnace Advantages:

1. The steel rod heating furnace is energy-saving and environmentally friendly, with high production efficiency. In terms of the power consumption of the intermediate frequency induction heating equipment, it is an energy-saving and environmentally friendly steel rod heating equipment manufacturer. Its induction heating equipment adopts an intermediate frequency induction heating power supply to control production. It can be used when the power is turned on, and the steel rod heating furnace is in The power consumption is much lower than other bar heating equipment, and it is as high as 35%.

2 The steel rod heating furnace has precise temperature control and good product quality. The quality of the workpiece after the treatment of the steel rod heating furnace is the same. A two-color infrared temperature measuring device is installed on the steel rod heating furnace to control the temperature of the steel rod heating electric furnace in real time, display in real time, uniform heating, and high qualified rate of finished products. The steel rod heating furnace has passed multi-level quality inspections, and the quality is guaranteed. Please rest assured to buy.

3. The steel rod heating furnace is of high quality and low price, reliable in use, and customized according to the user’s actual process needs and investment intentions. The steel rod heating furnace components adopt well-known brand manufacturers at home and abroad, and the performance is stable. long lasting.

Fourth, the characteristics of the steel rod heating furnace:

1. The steel rod heating furnace has high production efficiency, fast heating speed and less oxidation and decarburization.

2. The steel bar heating furnace has high reliability. Because our bar material diathermy production line has a unique circuit design and system power module unit, even if the individual power modules are damaged, the equipment can still work normally.

3. The steel rod heating furnace is energy-saving. Compared with the high frequency induction heating equipment of the electronic tube, our rod diathermy furnace can save 50% of the electricity and 70% of the water. Users can easily adjust the power supply, precisely control and select any heating conditions.

4. The steel rod heating furnace uses semiconductor devices, and the bar material heating furnace has a longer service life.

5. Steel rod heating furnace has low failure rate, high safety factor, simple structure and convenient maintenance