- 23

- Sep

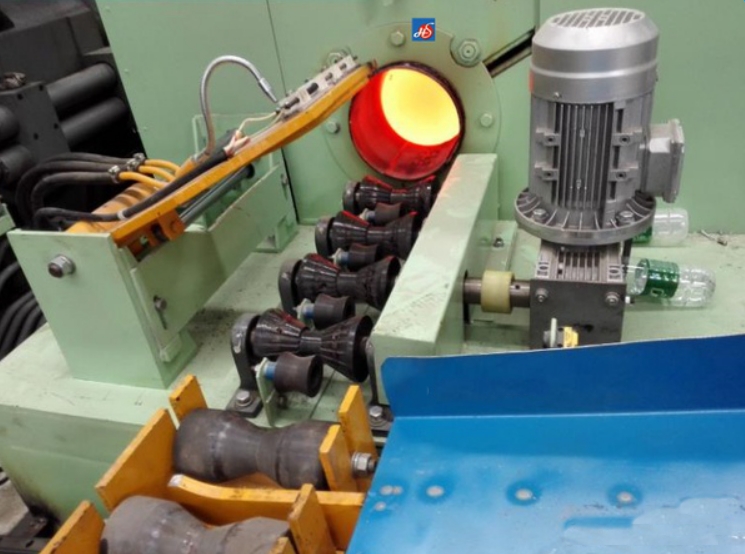

Intonga yensimbi yokushisa isithando somlilo

Intonga yensimbi yokushisa isithando somlilo

1. Amapharamitha wezobuchwepheshe wensimbi yokushisa isithando somlilo:

1. Izinto zokushisa zensimbi yokushisa esithandweni somlilo: i-carbon steel, i-alloy steel, insimbi engagqwali, i-titanium alloy steel, i-alloy aluminium, i-alloy yethusi nezinye izinto zensimbi

2. Ukushisisa induku yokushiswa yensimbi yokushisa isithando somlilo: ububanzi bezinsimbi eziyindilinga: 25mm-450mm; ubude bebanga: 50mm-12000mm

3. Ukushisa amandla wensimbi yokushisa isithando somlilo: 50KW-20000KW

4. Ukushisa kokushisa kwensimbi yensimbi yokushisa isithando somlilo: amathani angu-0.2-50 ngehora.

5. I-roller roller yokuguquguquka eguquguqukayo yesithando somlilo sensimbi: izinduku zensimbi zamadayimitha ahlukene zingaphakelwa ngejubane elifanayo. Ithebula le-roller ne-roller yokucindezela phakathi kwezidumbu zesithando zenziwe ngensimbi engagqwali engama-304 non-selehlile ngamanzi.

6. Ukusetshenziswa kwamandla kwensimbi yokushisa ibha yensimbi: Ukushisa ku-930 ℃ ~ 1050 ℃, ukusetshenziswa kwamandla 260 ~ 300 ℃.

7. Isilinganiso sokushisa kwe-infrared yensimbi yensimbi yokushisa isithando somlilo: idivaysi yokukala okushisa kwe-infrared ifakwa ekugcineni kokukhipha ukwenza ukushisa kwentambo yensimbi yokushisa kuhambisane.

8. Isithando sokufudumeza induku yensimbi sihlinzeka nge-remote operation console nge-touch screen noma ngohlelo lwekhompyutha lwezimboni ngokuya ngezidingo zakho.

9. Isithando sokufudumeza induku yensimbi sine-human-machine interface touch screen PLC uhlelo oluzenzakalelayo lokulawula okuhlakaniphile, kanye nemiyalo yokusebenza okusebenziseka kalula

2. Intonga yensimbi yokushisa isithando somlilo

Inqubo yensimbi yokushisa isithando somlilo: I-steel rod yokushisa isithando somlilo kulula ukusebenza. Idivayisi ye-infrared thermometer ye-American Leitai efakwe entanyeni yensimbi yokufudumeza umlomo wesithando somlilo, ekwazi ukuqapha nokulawula ukushisa kwebha phakathi nayo yonke inqubo yokucubungula nokulawula umjikelezo wokukhiqiza. Lapho isithando somlilo sensimbi siqala ukondla, i-thermometer ye-infrared izoshiya impahla yebha, ijikeleze i-engeli, bese kuthi induku yokududula izodudula impahla yebha iye kwi-heater yokungeniswa. I-roller elandelayo izodlulisela insimbi eyindilinga ekugcineni kwe-roller. Ngemuva kwalokho i-feeder idlulisela umugqa wensimbi emgqeni wokukhipha. Ngesikhathi sokuqaliswa, i-thruster izobuyela kokujwayelekile, bese isibhamu esilandelayo sidluliselwa ku-rack feeder. Ngasikhathi sinye, i-thermometer ye-infrared izobuyela endaweni yokulinganisa bese ithinta ikhanda leklabhu. Ngemuva kwalokho eyodwa yokudla nokukhulula iyaphela. Imvamisa, isithando somlilo sensimbi sizofakwa esithandweni sokubamba ukwenza insimbi eyindilinga ifudunyezwe ngokulinganayo.

3.I-rod rod yokushisa isithando somlilo Izinzuzo:

1. Isithando sokufudumeza induku yensimbi songa amandla futhi silondoloze imvelo, ngokusebenza kahle kokukhiqiza. Mayelana nokusetshenziswa kwamandla kwemishini yokufudumeza imvamisa ephakathi, kuyonga okonga amandla futhi kungumvelisi okhiqiza imishini yokushisa indonga. Imishini yayo yokufudumeza induction isebenzisa amandla aphakathi nendawo wokufaka amandla okushisa ukulawula ukukhiqizwa. Ingasetshenziswa lapho amandla evuliwe, kanti isithando somlilo sensimbi sisekusetshenzisweni kwamandla kuncane kakhulu kuneminye imishini yokushisa ibha, futhi ifinyelela kuma-35%.

2 Isithando sokufudumeza induku yensimbi sinokulawula okuqondile kokushisa kanye nekhwalithi yomkhiqizo omuhle. QualityIkhwalithi yomsebenzi wokusebenza ngemuva kokuphathwa kwesithando somlilo sensimbi iyafana. Idivayisi yokulinganisa ukushisa kwe-infrared efakwe kwi-steel rod yokushisa isithando somlilo ukulawula ukushisa kwensimbi yensimbi yokushisa isithando somlilo ngesikhathi sangempela, ukubonisa ngesikhathi sangempela, ukushisa okufanayo, kanye nezinga eliphezulu lemikhiqizo eqediwe. Isithando sokufudumeza induku yensimbi sidlulile ukuhlolwa kwekhwalithi ephezulu, futhi ikhwalithi iqinisekisiwe. Sicela uqiniseke ukuthi uyathenga.

3. Isithando sokufudumeza induku yensimbi sinekhwalithi ephezulu nentengo ephansi, inokwethenjelwa ekusetshenzisweni, futhi yenziwe ngezifiso ngokuya ngezidingo zenqubo zomsebenzisi kanye nezinhloso zokutshala imali. Izinsimbi zensimbi zokushisa isithando somlilo zamukela abakhiqizi bomkhiqizo abaziwayo ekhaya nakwamanye amazwe, futhi ukusebenza kuzinzile. ihlala isikhathi eside.

Okwesine, izici zensimbi yokushisa isithando somlilo:

1. Isithando sokufudumeza induku yensimbi sinokusebenza okuphezulu kokukhiqiza, isivinini sokushisa esisheshayo kanye namachibi amancane kanye ne-decarburization.

2. Isithando somlilo sokushisa ibha sinokwethenjelwa okuphezulu. Ngoba umugqa wethu wokukhiqiza we-bar material diathermy unomklamo oyingqayizivele wesekethe neyunithi yamandla wesistimu yamandla, noma ngabe amamojula wamandla ngamanye elimele, imishini isengasebenza ngokujwayelekile.

3. Isithando sokushisa induku yensimbi songa amandla. Uma kuqhathaniswa nemishini yokufudumeza efrikhwensi ephezulu yethubhu ye-elekthronikhi, isithando somlilo wethu wenduku singagcina u-50% kagesi no-70% wamanzi. Abasebenzisi bangalungisa kalula ukunikezwa kwamandla, balawule ngqo futhi bakhethe noma yiziphi izimo zokushisa.

4. Isithando sokufudumeza induku yensimbi sisebenzisa amadivayisi we-semiconductor, kanti isithando somlilo se-bar sinokuphila isikhathi eside.

5.I-steel rod yokushisa isithando somlilo inezinga eliphansi lokwehluleka, isici sokuphepha esiphakeme, isakhiwo esilula nokunakekelwa okulula