- 20

- Jan

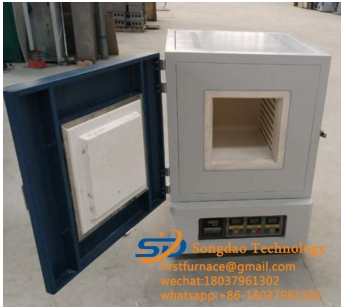

Isingeniso Sobuchwepheshe Bokwelashwa Kokushisa Kwebhokisi Lokumelana Nomlilo Wokuphikisa

Isingeniso se-Heat Treatment Technology ye Uhlobo Lwebhokisi Lokumelana Nomlilo

Isithando somlilo sokumelana nebhokisi siyindlela evamile yesithando somlilo kagesi, ihlukaniswe yaba mpo, enezingqimba, ehlukanisayo futhi ehlanganisiwe. Ububanzi bokushisa buhlukaniswe ngaphansi kwama-degree angu-1200, ama-degree angu-1400, ama-degree angu-1600, ama-degree angu-1700, ama-degree angu-1800, njll, ngokulandelana, kusetshenziswa ucingo lokumelana, izinduku ze-silicon carbide, izinduku ze-silicon molybdenum njengezakhi zokushisa, ezingakhethwa ngokuvumelana nezidingo. Isithando somlilo sikagesi sohlobo lwebhokisi ngokuvamile sisemoyeni. Ngaphandle kokushisa, kukhona nezithando zikagesi ezingadlula umkhathi futhi zingavalwa futhi zikhishwe nge-vacuum, ngezindlela ezihlukahlukene. Isetshenziswa kabanzi ekukhiqizeni nasekuhloleni i-ceramics, i-metallurgy, i-electronics, ingilazi, amakhemikhali, imishini, izinto eziphikisayo, ukuthuthukiswa kwezinto ezintsha, izinto ezikhethekile, izinto zokwakha kanye neminye imikhakha.

Kungenxa yokuthi isithando somlilo sokumelana nohlobo lwebhokisi sisetshenziswa kabanzi, ngakho-ke ezikoleni, kuma-laboratories, kuma-laboratories, amafekthri kanye namanye amabhizinisi amaningi, ungabona ukusetshenziswa kokushisa kwesithando somlilo nokudubula ingilazi, njll. Ingasetshenziswa futhi insimbi encane quenching , Annealing, tempering nokunye ukushisa ukwelashwa ukushisa. Yiqiniso, isithando somlilo sokumelana singasetshenziswa futhi njengokushisa okuphezulu kwezinsimbi, izitsha zobumba, ukuchithwa, ukuhlaziya, njll. Ake sibheke ukwethulwa kwesakhiwo sobuchwepheshe bokushisa ukushisa:

1. Igobolondo langaphandle lenziwe ngepuleti yensimbi egoqelwe ngamakhaza esezingeni eliphezulu, futhi indawo engaphezulu iphathwa ngobuchwepheshe bokufuthwa kwepulasitiki. Umnyango wesithando somlilo wamukela isakhiwo sokuvula ohlangothini, esibucayi ekuvuleni nasekuvaleni.

2. Isithando somlilo esiphakathi sokumelana nokushisa kwebhokisi sithatha isithando somlilo esivaliwe. Isici sokushisa senziwe nge-spiral shape ene-electric heat alloy wire, futhi sizungeze izindonga ezine zesithando somlilo. Ukushisa kwesithando somlilo kufana futhi impilo yesevisi inwetshiwe ngesikhathi sokushisa.

3. Isithando somlilo esinezinga eliphezulu lokushisa kweshubhu sisebenzisa amashubhu okushisa aphezulu, futhi sisebenzisa izinti ze-silicon carbide njengezinto zokufudumeza ukuze zifakwe kubhantshi yesithando somlilo.

4. Isithando somlilo sokumelana nohlobo lwebhokisi lokushisa okuphezulu sisebenzisa izinti ze-silicon carbide njengezinto zokushisa, ezifakwe ngokuqondile esithandweni, futhi izinga lokusetshenziswa kokushisa liphezulu.

5. Izitini ze-foam ezilula ezingasindi kanye ne-aluminium silicate fiber ukotini zisetshenziswa njengezinto zokufakelwa kwezithando zokushisa ukuze kuncishiswe isitoreji sokushisa kanye nokushisa okushisayo, okuholela ekugcinweni okukhulu kokushisa esithandweni futhi kufinyezwe isikhathi sokushisa, ukuphakama okuphansi kwezinga lokushisa, ukulahlekelwa okuncane okungenalutho kwesithando somlilo. isilinganiso, kanye nokusetshenziswa kwamandla Futhi kwehle kakhulu.

6. Izilawuli zesithando somlilo esimelana nohlobo lwebhokisi zihlukaniswe zibe: uhlobo lwesikhombi, uhlobo lwesibonisi sedijithali, kanye nohlobo lokulawula lwama-multi-band amakhompyutha amancane