- 20

- Jan

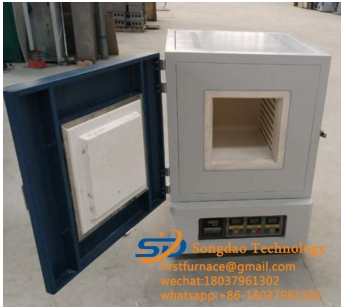

Introduction to Heat Treatment Technology of Box Type Resistance Furnace

Introduction to Heat Treatment Technology of Box Type Resistance Furnace

Box-type resistance furnace is a common form of electric furnace, divided into vertical, horizontal, split and integrated. The temperature range is divided into below 1200 degrees, 1400 degrees, 1600 degrees, 1700 degrees, 1800 degrees, etc., respectively, using resistance wire, silicon carbide rods, silicon molybdenum rods as heating elements, which can be selected according to needs. The box-type electric furnace is usually in the air. In addition to heating, there are also electric furnaces that can pass atmosphere and can be sealed and vacuumed, in various forms. It is widely used in the production and experiment of ceramics, metallurgy, electronics, glass, chemicals, machinery, refractory materials, new material development, special materials, building materials and other fields.

It is precisely because the box-type resistance furnace is widely used, so in schools, laboratories, laboratories, factories and many other enterprises, you can see the application of resistance furnace heat treatment and glass firing, etc. It can also be used for general small steel quenching , Annealing, tempering and other heat treatment heating. Of course, the resistance furnace can also be used as high heat for metals, ceramics, dissolution, analysis, etc. Let’s take a look at the introduction of heat treatment technology structure:

1. The outer shell is made of high-quality cold-rolled steel plate, and the surface is treated with plastic spray technology. The furnace door adopts a side-opening layout, which is sensitive to opening and closing.

2. The medium temperature box-type resistance furnace adopts a closed furnace. The heating element is made of a spiral shape with electric heating alloy wire, and it surrounds the four walls of the furnace. The furnace temperature is uniform and the service life is extended during heat dissipation.

3. The high-temperature tubular resistance furnace uses high-temperature combustion tubes, and uses silicon carbide rods as heating elements to install in the furnace jacket.

4. The high-temperature box-type resistance furnace uses silicon carbide rods as heating elements, which are directly installed in the furnace, and the heat utilization rate is high.

5. Lightweight foam insulation bricks and aluminum silicate fiber cotton are used as insulation materials for resistance furnaces to reduce heat storage and thermal conductivity, resulting in large heat storage in the furnace and shortening the heating time, low surface temperature rise, low empty furnace loss rate, and power consumption Also greatly reduced.

6. Box-type resistance furnace controllers are divided into: pointer type, digital display type, and microcomputer multi-band control type