- 09

- Sep

Induction incibilikisa isithando somlilo

Induction incibilikisa isithando somlilo

Induction melting fire is a induction heating equipment used to heat iron oncibilikisiwe. It is kabanzi embonini Foundry. Yiziphi izinhlelo zokuncibilikisa isithando somlilo? Imininingwane elandelayo uhlelo lokuncibilika kwesithando somlilo esincibilikisa.

1. Ngokwendlela yokupholisa ye-transformer, idivaysi yokuphakelwa kwamandla kwe-induction melting furnace system-transformer ingahlukaniswa ibe yizinhlobo ezimbili: i-transformer yohlobo olomile ne-transformer egxiliswe ngamafutha. Emkhakheni we-induction oncibilikisa isithando somlilo, sivame ukusebenzisa i-induction melting furnace rectifier transformers. Lolu hlobo lwe-transformer luyi-transformer egxilise uwoyela, ephakeme kakhulu kunama-transformer ajwayelekile ngokwamandla we-overload kanye nekhono lokulwa nokuphazamiseka.

2. Ukunikezwa kwamandla okuvama okuphakathi kokungeniswa kwesithando somlilo: Ikhabethe lokuphakelwa kwamandla wamandla aphakathi nendawo liyingxenye esemqoka yohlelo lokuncibilikisa isithando somlilo. Ukunikezwa kwamandla okuphakathi okuphakathi kwenziwa nge-rectifier kanye ne-inverter, i-capacitor bank, i-thyristor, i-AC contactor, nekhebula elipholile ngamanzi.

3. Umsebenzi wekhabethe le-capacitor yohlelo lokuncibilikisa isithando somlilo ukuhlinzeka ngesinxephezelo samandla esisebenzayo sekhoyili yokungeniswa. Kungamane kuqondwe ukuthi usayizi we-capacitor uthinta ngqo amandla edivayisi. Kumele kuqashelwe ukuthi i-capacitance yedivayisi efanayo uhlobo olulodwa kuphela lwe-resonant capacitance (i-electrothermal capacitance). Ngaphezu kwama-elementi ama-resonant capacitor element (ama-capacitors), ama-capacitor wokuhlunga akhetha kakhulu. Lokhu futhi kuyizinga likazwelonke elingasetshenziswa ukunquma ukuthi ngabe idivayisi iyithuluzi elihambisanayo noma elichungechunge.

4. Umzimba wesithando somlilo oshisayo. Umzimba wesithando somlilo oshisayo osetshenziswayo usetshenziselwa ukushisa kwensimbi nokuncibilika. Ibizwa ngokuthi i-inductor noma ikhoyili ye-inductor. Ngokuya ngegobolondo lesithando somlilo, ihlukaniswe yaba ngumzimba wesithando somlilo noma igobolondo le-aluminium.

5. Amanzi okupholisa wohlelo lokuncibilikisa isithando somlilo. Uhlelo lokulawulwa kwamanzi okupholisa luyingxenye ebaluleke kakhulu yohlelo lokuncibilikisa isithando somlilo. Futhi kuyingxenye ebaluleke kakhulu. Kungashiwo ukuthi ikhwalithi yohlelo lokupholisa ingathinta ngqo isinqumo. Izinga lokwehluleka kohlelo lokuncibilikisa isithando somlilo liyathuthukiswa. Okwamanje kunezindlela ezintathu ezisetshenziswayo zokuncibilikisa iziko lesithando somlilo, ukupholisa kwamachibi wendabuko, umbhoshongo wokupholisa ovulekile, nombhoshongo wokupholisa ovaliwe ..

Ukupholisa amachibi kuthatha isikhala esiningi namanzi okupholisa. Izinga lamanzi liphansi futhi kulula ukukala. Manje ngokuyisisekelo akusizi ngalutho. Umbhoshongo wokupholisa ovulekile unomthwalo omkhulu wokupholisa, izindleko eziphansi, kanye nonyawo olulinganiselayo. Manje sesinemithambo emikhulu yesithando somlilo esisebenza kakhulu. Ngenxa yekhwalithi yamanzi abandayo, ikhabethe lamandla alinconywa. Umbhoshongo wokupholisa ovaliwe unezinzuzo zokuthi amanzi ajikelezayo angavalwa ngokuphelele ukuhlukanisa ithonya lemvelo yangaphandle yemakethe. Inkinga yekhwalithi yamanzi ingaqinisekiswa ngempumelelo futhi ukusetshenziswa kwamanzi kuncane. Indawo incane futhi namandla okupholisa makhulu. Kuyindlela evame ukusetshenziswa yokupholisa manje ..

6. Isiteshi se-hydraulic sohlelo lokuncibilikisa isithando somlilo

Ingcindezi ye-hydraulic ye-induction melting furnace system isetshenziselwa ukuncibilikisa isithando somlilo. Ngokuvamile, umzimba owodwa wesithando unamasilinda amabili wokubacindezela, ahlanganiswe nengcindezi yokubacindezela ukwakha uhlelo lwesithando somlilo. Isithando somlilo esibhekelela amandla omzimba sinezinzuzo zokuzinza okuvelele nokukwazi ukuhlala kunoma isiphi isikhundla. Le yingxenye ebalulekile yohlelo lokuncibilikisa isithando somlilo sonke.

Imisebenzi okufanele ibe nayo isiteshi samanzi yile elandelayo

1) Iphampu kawoyela kufanele isebenzise iphampu yegiya, enezinzuzo zokucindezela ukusebenza okuzinzile nomsindo ophansi;

2) Amafutha opholile kufanele afakelwe (ukupholisa amanzi kungcono kakhulu, ukupholisa umoya kungasetshenziselwa iziteshi ezincane ezibamba amanzi);

3) itheku kawoyela nembobo yokubuya kumele ibe nezihlungi zokususa ukungcola endaweni yokupholisa;

4) Umzimba wethangi, ishubhu, njll.

7. Izinto zokuxhuma zesistimu yokuncibilikisa isithando somlilo, ukuxhumeka kwesiguquli kwikhabhinethi yamandla, nokuxhuma ibha yethusi / i-aluminium bar uxhumano kuyakhethwa. Ukuxhuma phakathi kwekhabethe lokuphakelwa kwamandla amaphakathi okuphakathi kanye ne-capacitor kwenziwa ngocingo lwethusi, futhi ukuxhumana phakathi kwesithando somlilo kanye ne-capacitor kuxhunywe ngentambo epholile yamanzi, futhi ubude abukho ngaphezu kwamamitha ayi-6.

8. isithando somlilo esincibilikisa liqukethe:

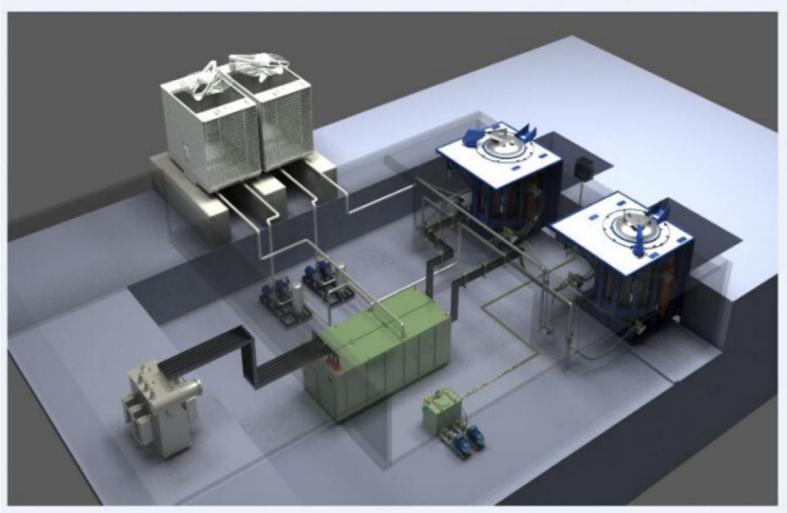

Ukunikezwa kwamandla okuvama okulingene – ikhabethe le-capacitor – igobolondo le-aluminium noma isithando somlilo segobolondo – Isistimu yesithando somlilo wokubacindezela – ibhokisi lesilawuli kude – Umbhoshongo wokupholisa umjikelezo ovaliwe.

9. inani ukuchithwa kwesithando somlilo

Intengo yesithando somlilo esincibilika ibalwa ngokusho kwamandla wokunikezwa kwamandla okuvama okuphakathi kanye nevolumu yomzimba wesithando. Izintengo ezihlukile zokumisa ziyahlukahluka. Le ntengo ingeyenkomba kuphela. Xhumana nathi sizoba nentengo ephansi kakhulu, sicela ubheke inani elithile.I-Firstfurnace@gmail.com

| Amandla (T) | imodeli | amandla ukalwe (KW) | intengo u (yuan) |

| 250 | I-KGPS-250 | 250 | inani: ¥ 70500RMB |

| 0.5 | I-KGPS-400 | 400 | inani: ¥ 148800RMB |

| 0.75 | I-KGPS-600 | 600 | inani: ¥ 180000RMB |

| 1 | I-KGPS-800 | 800 | inani: ¥ 221000RMB |

| 1.5 | I-KGPS-1200 | 1200 | inani: ¥ 300000RMB |

| 2 | I-KGPS-1600 | 1600 | inani: ¥ 361500RMB |

| 3 | I-KGPS-2000 | 2000 | inani: ¥ 447000RMB |

| 5 | I-KGPS-3000 | 3000 | inani: ¥ 643000RMB |

| 6 | I-KGPS-3500 | 3500 | inani: ¥ 700000RMB |

Ukukhethwa kokucushwa okuhlobene kwe-induction melting furnace

| imodeli | umthamo | Amandla wokulinganisa | imvamisa | voltage Input | Amandla kagesi we-MF | Isikhathi sokukha amanzi | ukusetshenziswa kwamandla | I-transformer |

| T | KW | KHZ | V | V | Amaminithi / T. | KWH / T. | I-KVA | |

| I-KGPS-250 | 0.25 | 250 | 1 | 380 | 750 | 65 | 680 | 300 |

| I-KGPS-400 | 0.5 | 400 | 1 | 380 | 1600 | 65 | 680 | 400 |

| I-KGPS-500 | 0.75 | 500 | 1 | 380 | 1600 | 65 | 650 | 600 |

| I-KGPS-700 | 1 | 700 | 0.7 | 660 | 2400 | 60 | 640 | 800 |

| I-KGPS-1000 | 1.5 | 1000 | 0.7 | 660 | 2400 | 60 | 640 | 1000 |

| I-KGPS-1500 | 2 | 1500 | 0.5 | 660 | 2400 | 65 | 640 | 1500 |

| I-KGPS-2000 | 3 | 2000 | 0.5 | 950 | 3200 | 65 | 640 | 1800 |

| I-KGPS-3000 | 5 | 3000 | 0.5 | 950 | 3200 | 70 | 620 | 2500 |

| I-KGPS-4000 | 6 | 4000 | 0.5 | 950 | 3600 | 70 | 600 | 3150 |

| I-KGPS-4500 | 8 | 4500 | 0.3 | 950 | 3600 | 70 | 580 | 4000 |

Ukulungiswa okujwayelekile kwesithando somlilo esonga amandla

| Uhlu lokucushwa kwesithangami esindisa amandla | ||||

| CHA. | Igama | Unit | ubuningi | khumbula |

| 1 | UMA ugesi | Misa | 1 | Standard |

| 2 | Ibhokisi lesinxephezelo seCapacitor | isethi | 1 | Standard |

| 3 | Amandla kagesi esithandweni somlilo | isethi | 1 | Standard |

| 4 | Hlukanisa ikhebula lokuxhuma | PC | 1 | Standard |

| 5 | Ikhebula elipholiwe lokukhipha amanzi | isethi | 1 | Standard |

| 6 | ibhokisi lokulawula | PC | 1 | Standard |

12. Ungasihlela kanjani isithando somlilo esincibilikayo? Sicela ubheke lesi sibalo esingezansi ukuthola izimpendulo.

I-13, induction incibilikisa isakhiwo sokubukeka kwesithando