- 20

- Sep

Periodic induction heating furnace for circular workpieces

Periodic induction heating furnace for circular workpieces

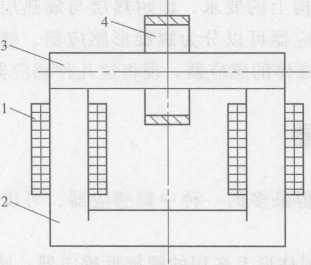

Schematic diagram of a periodic induction heating furnace for toroidal workpieces. The ring workpiece 4 is sleeved on the movable magnet 3, 2 is a fixed magnet, and 1 is an induction coil. This induction heating method is suitable for workpieces with low heating temperature, large diameter, short length and thin wall thickness. The advantage is that this kind of inductor has a high power factor, it can be compensated without a capacitor, and the power used is not large, and it can be directly connected to the power supply of the production workshop. In machinery manufacturing and automobile manufacturing, the bearing ring and gear ring are preheated to 80-100t by power frequency induction, and then heat-sleeved on the shaft. After cooling, they are locked together with the shaft without using a key connection

.

Figure 4-13 Schematic diagram of periodic induction heating furnace for ring workpieces

1—Induction coil 2—Fixed magnet 3—Moving magnet 4—Ring workpiece