- 24

- Sep

Strip transverse magnetic field induction heating annealing treatment form

Strip transverse magnetic field induction heating annealing treatment form

The transverse magnetic field heating annealing process is roughly divided into two forms: vertical annealing unit and horizontal production line.

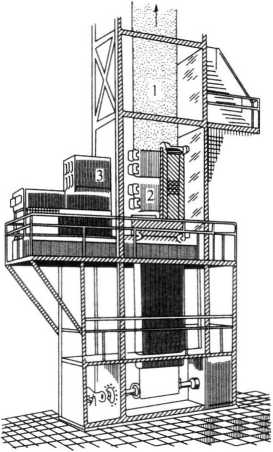

(1) Vertical annealing unit The figure shows a vertical annealing unit for steel strip transverse magnetic field induction heating. The unit is composed of main parts such as unwinding, traction, rewinding, tension control, inductor, and intermediate frequency power supply. It is mainly used for softening and annealing the carbon steel belt.

(1) Vertical annealing unit The figure shows a vertical annealing unit for steel strip transverse magnetic field induction heating. The unit is composed of main parts such as unwinding, traction, rewinding, tension control, inductor, and intermediate frequency power supply. It is mainly used for softening and annealing the carbon steel belt.

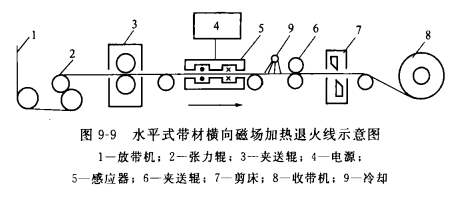

The horizontal layout of the steel strip transverse magnetic induction heating annealing production line is shown in Figure 9-9. The forward speed of the steel belt is mainly determined by the speed of the tractor of the take-up machine. At the same time, the tension of the steel strip during annealing is adjusted by the tension spoke. After annealing, the steel strip is cooled by spraying water with a shower. The heating temperature and heating power of the steel strip are regulated by the electronic control system.

The above briefly introduces two semi-industrial test equipment used in the transverse magnetic field induction heating annealing treatment of strips for reference.