- 02

- Oct

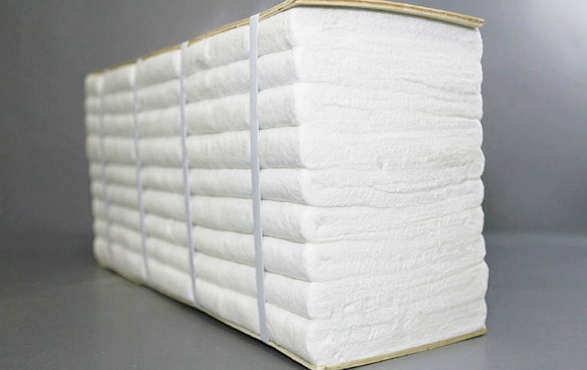

Ceramic fiber module

Ceramic fiber module

Classification temperature:

Common type aluminum silicate fiber composite block 1100℃

Standard type aluminum silicate fiber composite block 1260℃

High-purity aluminum silicate fiber composite block 1260℃

High-aluminum type aluminum silicate fiber composite block 1360℃

Zirconium-containing aluminum silicate fiber composite block 1430℃

Production Process:

Various aluminum silicate refractory fiber modules are made of fiber needle-punched blankets of corresponding materials with excellent properties according to the structure and size of the fiber modules, and are made by professional technicians with special equipment for module processing to ensure the completion of the wall lining. The rear blocks are extruded to form a seamless and tight heat-preserving whole, which maintains a certain amount of compression during the production process. The product supporting anchor system can be firmly connected to the kiln shell, with accurate dimensions and easy installation. The construction speed of the furnace lining is accelerated, the weight of the furnace is reduced, and the refractory and thermal insulation performance of the furnace is greatly improved. Users can use different fiber blocks according to the structure of the kiln. Our company can provide multi-variety, multi-system fiber blocks, and can also be processed according to user requirements. To

Technical characteristics:

Low heat capacity, low thermal conductivity

Excellent thermal stability, thermal shock resistance

Excellent heat flow resistance and high mechanical strength. Excellent elasticity, because the fiber blocks are made to maintain a certain amount of compression, the fiber blocks themselves expand and squeeze the lining without gaps, and the fiber lining can shrink, thereby improving the thermal insulation performance of the fiber lining. To

The installation is simple and fast, the anchor is built-in, and the safety performance is good. To

Application:

Various heating furnaces for metallurgical iron and steel. Ladle cover heat treatment furnace, annealing furnace, bell furnace. To

Ceramic shuttle kiln, horseshoe kiln, tunnel kiln and other porcelain kilns, kiln cars, kiln doors. To

Petrochemical cracking furnace, reforming furnace, atmospheric and vacuum furnace, coking furnace, flue. To

Other types of industrial furnaces, such as soaking furnaces, crucible furnaces, resistance furnaces and other high-temperature thermal equipment.

index:

| Product name | normal type | Standard | High purity type | High aluminum type | Zirconium-containing type | |

| project | 1100 | 1260 | 1260 | 1360 | 1430 | |

| Classification temperature (℃) | <1000 | 1050 | 1100 | 1200 | 1350 | |

| Working temperature (℃) | 220±15 | 220±15 | ||||

| chemical components

(%) |

AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

| AL2O3+SIO2 | 96 | 97 | 99 | 99 | - | |

| AL2O3+SIO2+ZrO2 | - | - | - | - | 99 | |

| ZrO2 | - | - | - | - | 15-17 | |

| Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | |

| Na2O+K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | |

| Product Size

(mm) |

Common specifications: 600×240-300×100-200 (without anchors) 300×300×250 (with anchors)

Other structural combination blocks can be made according to the drawings provided by the user |

|||||

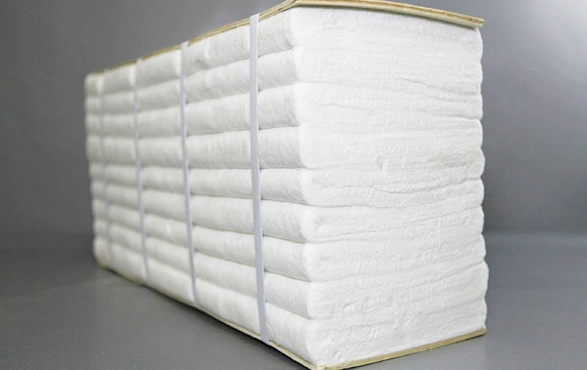

Ceramic fiber module

Classification temperature:

Common type aluminum silicate fiber composite block 1100℃

Standard type aluminum silicate fiber composite block 1260℃

High-purity aluminum silicate fiber composite block 1260℃

High-aluminum type aluminum silicate fiber composite block 1360℃

Zirconium-containing aluminum silicate fiber composite block 1430℃

Production Process:

Various aluminum silicate refractory fiber modules are made of fiber needle-punched blankets of corresponding materials with excellent properties according to the structure and size of the fiber modules, and are made by professional technicians with special equipment for module processing to ensure the completion of the wall lining. The rear blocks are extruded to form a seamless and tight heat-preserving whole, which maintains a certain amount of compression during the production process. The product supporting anchor system can be firmly connected to the kiln shell, with accurate dimensions and easy installation. The construction speed of the furnace lining is accelerated, the weight of the furnace is reduced, and the refractory and thermal insulation performance of the furnace is greatly improved. Users can use different fiber blocks according to the structure of the kiln. Our company can provide multi-variety, multi-system fiber blocks, and can also be processed according to user requirements. To

Technical characteristics:

Low heat capacity, low thermal conductivity

Excellent thermal stability, thermal shock resistance

Excellent heat flow resistance and high mechanical strength. Excellent elasticity, because the fiber blocks are made to maintain a certain amount of compression, the fiber blocks themselves expand and squeeze the lining without gaps, and the fiber lining can shrink, thereby improving the thermal insulation performance of the fiber lining. To

The installation is simple and fast, the anchor is built-in, and the safety performance is good. To

Application:

Various heating furnaces for metallurgical iron and steel. Ladle cover heat treatment furnace, annealing furnace, bell furnace. To

Ceramic shuttle kiln, horseshoe kiln, tunnel kiln and other porcelain kilns, kiln cars, kiln doors. To

Petrochemical cracking furnace, reforming furnace, atmospheric and vacuum furnace, coking furnace, flue. To

Other types of industrial furnaces, such as soaking furnaces, crucible furnaces, resistance furnaces and other high-temperature thermal equipment.

index:

| Product name | normal type | Standard | High purity type | High aluminum type | Zirconium-containing type | |

| project | 1100 | 1260 | 1260 | 1360 | 1430 | |

| Classification temperature (℃) | <1000 | 1050 | 1100 | 1200 | 1350 | |

| Working temperature (℃) | 220±15 | 220±15 | ||||

| chemical components

(%) |

AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

| AL2O3+SIO2 | 96 | 97 | 99 | 99 | - | |

| AL2O3+SIO2+ZrO2 | - | - | - | - | 99 | |

| ZrO2 | - | - | - | - | 15-17 | |

| Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | |

| Na2O+K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | |

| Product Size

(mm) |

Common specifications: 600×240-300×100-200 (without anchors) 300×300×250 (with anchors)

Other structural combination blocks can be made according to the drawings provided by the user |

|||||