- 23

- Nov

Factors influencing the effect of argon blowing and venting bricks at the bottom of ladl

Factors influencing the effect of argon blowing and venting bricks at the bottom of ladle

The quality of the use of argon-blown venting bricks at the bottom of the ladle is very important to steel manufacturers. During use, adverse factors should be avoided or dealt with as much as possible; the factors that affect the effect of argon-blown venting bricks at the bottom of the ladle are steel infiltration on the working surface of the ventilating bricks. , Air-permeable bricks (slit type) are blocked by molten slag, material changes, air source pressure fluctuations, and long time to stop the package.

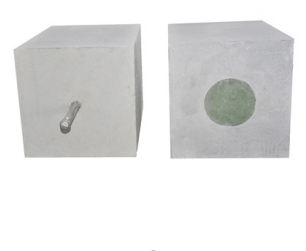

The working conditions of the breathable bricks are very harsh. The static pressure of the molten steel in the large ladle is large, and the required stirring strength is also great. Therefore, the key to ensuring the air permeability is that the breathable bricks have a strong anti-seepage steel ability. In the production practice of steel manufacturers, the working surface of ventilating bricks often forms steel, so it is necessary to clean the working surface with an oxygen lance. If the slit-type ventilating brick is not cleaned, it will easily occur that the ventilating brick is not ventilated.

(Picture) Slit-type breathable brick

After the ladle is continuously cast, the working surface of the ventilating brick is fully in contact with the slag, and the slag will continuously infiltrate the interior of the ventilating brick. As the temperature of the ladle decreases, the viscosity of the steel slag continues to increase, and the slit passage of the ventilating brick is likely to be blocked. As a result, the amount of air blown at the bottom of the ladle is small or airtight.

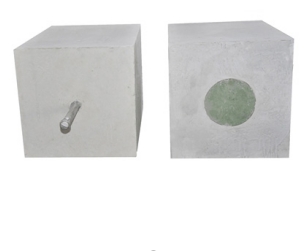

Breathable brick is a multi-element and multi-phase composite material, and has the structural characteristics of particles, mechanical properties, interfaces, and pores. The main chemical composition of the air-permeable brick is alumina, followed by a certain amount of magnesium oxide. Due to the different chemical composition, the density, compressive strength, and flexural strength of the air-permeable brick will be different.

(Picture) Impermeable Breathable Brick

In the actual use of the ventilating brick, the argon gas supply pressure will fluctuate due to many reasons. When the argon pressure is too low, the molten steel cannot be blown and the bottom blowing fails; when the argon pressure is too high, the molten steel is easily turned up seriously, and after contact with air, the molten steel will be oxidized again.

When the ladle is stopped for too long, the baking time is insufficient or not baking, the temperature of the inner lining of the ladle is not enough. After the steel is connected, the temperature of the molten steel at the bottom of the ladle is low, and the cold steel is attached to the bottom of the ladle, which hinders the blowing of the ventilating brick at the bottom, resulting in ventilation fail.

Firstfurnace@gmil.com has domestic leading production equipment and first-class production technology, and is the country’s largest manufacturer of argon blowing and venting bricks with a production capacity of 120,000 sets. At present, our company has developed various types of argon-blowing air-permeable bricks at the bottom of ladle, and the performance has reached or exceeded that of similar imported products. Good results have been achieved in use and are well received by users!