- 03

- Feb

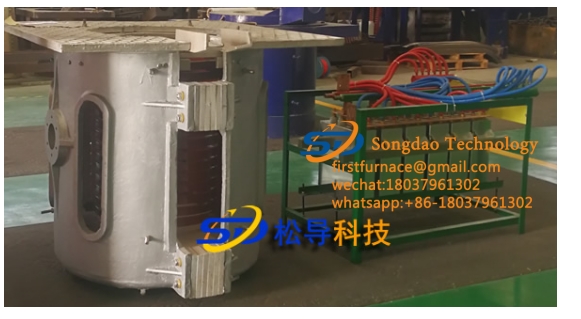

Induction melting furnace is an indisputable position used as melting equipment in the foundry

Induction melting furnace is an indisputable position used as melting equipment in the foundry

Performance comparison between intermediate frequency induction melting furnace and power frequency induction melting furnace (take cast iron as an example)

| Serial number | Comparison index | Medium frequency induction melting furnace | Power frequency induction melting furnace | Comment |

| 1 | Power density | 600-1400 kW/t | 300 kW/t | The allowable value of configuration power density per ton of furnace capacity varies with frequency |

| 2 | Melting operation method | Batch melting | Residual liquid melting method | |

| 3 | Requirements for adding materials | Small requirements | High standard | |

| 4 | Melting unit consumption | 500 ~ 550 kWh/t | 540 ~ 580 kWh/t | Due to the high power density of the intermediate frequency induction melting furnace, the small heat loss, short melting time, and high overall efficiency |

| 5 | Power adjustment range | 0~100% stepless adjustment | Step adjustment | The power adjustment of the industrial frequency furnace also involves the adjustment of the three-phase balance, which is more complicated |

| 6 | Automatic power adjustment | Can | difficulty | |

| 7 | The stirring effect of the melt | Adjustable | Large and fixed | The stirring effect of the intermediate frequency induction melting furnace changes inversely with the change of frequency |

| 8 | Power consumption ratio | 30 ~ 40% | 100% | |

| 9 | Power repair amount | Smaller | Bigger | |

| 10 | Fault diagnosis and protection function | Completely, strong | Partly | |

| 11 | Possibility to connect to the computer | Can | difficulty | Intermediate frequency induction melting furnace can be connected with the automatic control and management system of the computer melting process |

| 12 | Total investment ratio | ~ 90% | 100% |

Allowable values of electric furnace power density at different frequencies (cast iron and steel)

| Frequency (Hz) | 1000 | 500 | 250 | 125 | 50 |

| Electric furnace capacity (t) | 0.2~1.5 | 0.6~6 | 1.1~18 | 2.5~60 | 8~100 |

| Power density (kW/t) | 1345 | 945 | 670 | 475 | 300 |

The higher the operating frequency of the electric furnace, the higher the allowable power density value. At present, the power density of medium frequency induction melting furnaces manufactured abroad is usually configured to 600-800 kW/t, and the power density configuration of small-capacity melting furnaces can be as high as 1000 kW/t. The power density of domestically manufactured intermediate frequency induction melting furnaces is usually configured to about 600 kW/t. This mainly takes into account the two factors of the service life of the furnace lining and the production management, because the furnace lining working under the condition of high power density is washed by the strong melt stirring effect.

From the above analysis, it can be seen that compared with the power frequency induction furnace, the intermediate frequency induction melting furnace has an indisputable status as a melting device in a modern foundry in terms of technical performance, operational performance and investment.