- 23

- Feb

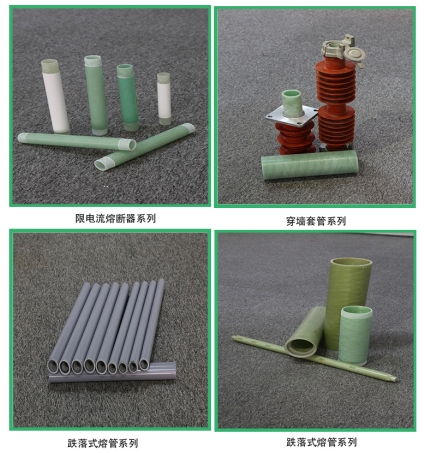

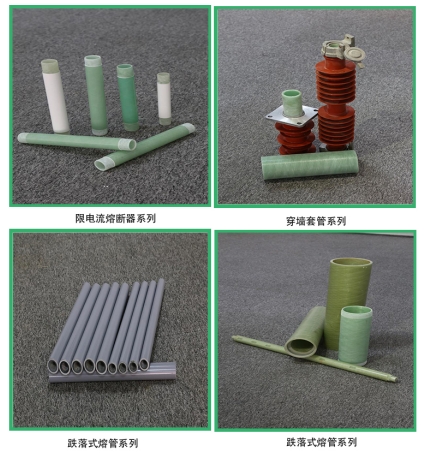

Epoxy glass fiber wall pipe

Basic parameters of epoxy glass fiber wall pipe:

1: Winding angle, 45~65 (the winding angle can be adjusted according to different requirements to achieve better mechanical performance requirements);

2: Fiber content (weight ratio), 70~75%;

3: Density, 2.00 g/cm3;

4: Water absorption rate, less than 0.03%;

5: Axial thermal expansion coefficient, 1.8 E-05 1/K;

6: Glass transition temperature, 110~120 ℃;

7: Chemical resistance. Mineral oil: excellent;

8: Solvent and dilute acid: excellent;

9: Tensile modulus of elasticity, axial 14000 MPa;

10: Tensile strength; axial 280 MPa; circumferential 600 MPa;

11: Shear strength: 150 MPa;

12: Flexural strength: 350 MPa in axial direction;

13: Compressive strength: axial 240 MPa;

14: Relative permittivity 2-3.2;

15: Dielectric loss factor 0.003-0.015;

16: Partial discharge capacity ≤5;

17: Insulation strength: axial 3~6 kV; radial 10~12 kV;

18: Lightning impact: 110 KV

19: Power frequency shock: 50 KV;

20: Heat resistance grade: B, F, H grade

21: Inner diameter>5mm; outer diameter<300mm; length<2000mm.

环氧玻璃纤维穿墙管

环氧玻璃纤维穿墙管基本参数:

1:缠绕角 ,45~65(可以根据不同要求调整缠绕的角度来达到更好力学性能要求);

2:纤维含量(重量比), 70~75% ;

3:密度, 2.00 g/cm3 ;

4:吸水率, 小于0.03 % ;

5:轴向热膨胀系数 ,1.8 E-05 1/K ;

6:玻璃转化温度 ,110~120 ℃;

7:耐化学性能 矿物油:极好;

8:溶剂及稀酸:优 ;

9:抗拉弹性模量,轴向 14000 MPa ;

10:抗拉强度;轴向 280 MPa ;环向 600 MPa ;

11:抗剪强度 :150 MPa ;

12:抗弯强度: 轴向 350 MPa ;

13:抗压强度:轴向 240 MPa;

14:相对介电常数 2-3.2 ;

15:介质损耗因数 0.003-0.015 ;

16:局部放电量 ≤5 ;

17:绝缘强度: 轴向 3~6 kV ; 径向 10~12 kV ;

18:雷电冲击: 110 KV

19:工频冲击: 50 KV ;

20:耐热等级: B、F、H级

21:内径 >5mm;外径 <300mm;长度<2000mm。

Epoxy glass fiber wall pipe

Basic parameters of epoxy glass fiber wall pipe:

1: Winding angle, 45~65 (the winding angle can be adjusted according to different requirements to achieve better mechanical performance requirements);

2: Fiber content (weight ratio), 70~75%;

3: Density, 2.00 g/cm3;

4: Water absorption rate, less than 0.03%;

5: Axial thermal expansion coefficient, 1.8 E-05 1/K;

6: Glass transition temperature, 110~120 ℃;

7: Chemical resistance. Mineral oil: excellent;

8: Solvent and dilute acid: excellent;

9: Tensile modulus of elasticity, axial 14000 MPa;

10: Tensile strength; axial 280 MPa; circumferential 600 MPa;

11: Shear strength: 150 MPa;

12: Flexural strength: 350 MPa in axial direction;

13: Compressive strength: axial 240 MPa;

14: Relative permittivity 2-3.2;

15: Dielectric loss factor 0.003-0.015;

16: Partial discharge capacity ≤5;

17: Insulation strength: axial 3~6 kV; radial 10~12 kV;

18: Lightning impact: 110 KV

19: Power frequency shock: 50 KV;

20: Heat resistance grade: B, F, H grade

21: Inner diameter>5mm; outer diameter<300mm; length<2000mm.