- 26

- Jul

Plasma induction furnace

- 26

- Jul

Plasma induction furnace

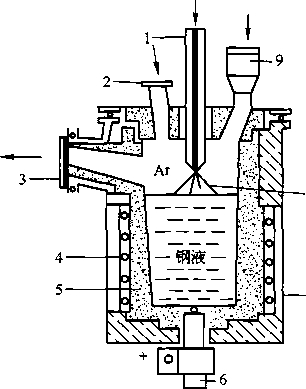

In addition to the above-mentioned various types of induction furnaces, there are also plasma induction furnaces and electroslag induction furnaces. Plasma induction furnace is a kind of smelting equipment that appeared in the 1970s. It is a combination of an ordinary induction furnace and a plasma arc heating device. The intermediate frequency induction furnace is equipped with a closed furnace shell, or a sealed top is added to the spiral. The cover is equipped with a plasma gun, and the bottom of the Tansuo is equipped with a bottom electrode, as shown in Figure 2-1.

In addition to the induction furnace power supply, the power supply also has a plasma arc power supply. Small-capacity furnaces only have induction heating coils, and large-capacity furnaces include induction heating and stirring coils. The bottom plate of the ground scroll is equipped with a water-cooled anode, and there is a hole in the center of the furnace cover for the plasma gun body to extend into the furnace (the plasma gun is divided into two types: DC and AC). The gun body and the furnace cover must be sealed and cooled with water. The furnace cover has a charging hopper and an observation window. The furnace shell structure is divided into two types: fully enclosed and semi-enclosed.

In ordinary induction furnace smelting, the slag is heated by molten steel, and the temperature of the slag is lower than that of the molten steel, so the slag refining capacity is low. Plasma arc can heat the slag, overcoming the shortcomings of low temperature of ordinary induction slag, and the sealing of plasma induction furnace can form a protective atmosphere, therefore, it can significantly improve the refining ability of slag. Plasma induction furnace can be used to smelt ultra-low carbon stainless steel, fine sealing alloy and other materials, and its quality reaches or approaches the level of vacuum electric arc furnace.

Figure 2-1 Plasma induction furnace

1 a plasma gun; 2—observation hole; 3—steel outlet; 4—sensor;