- 18

- Oct

Big gear hardening machine

Big gear hardening machine

Equipment characteristics of large gear hardening machine

- Since the power of the power supply is relatively small, it is sufficient to use 6 pulses, and its harmonics to the power grid will not exceed the standard. The principle of the main circuit is shown in the figure below.

(2) The control circuit is fully digital and integrated, and there is no relay control loop, which ensures the reliability and anti-interference ability of the equipment:

(3) Constant power output of the power supply can ensure high power factor

(4) Has excellent impact load resistance

(5) Perfect and reliable protection function

This control circuit is equipped with various protection measures such as overcurrent, overload, overvoltage, lack of phase, undervoltage of control power supply, low cooling water pressure and high cooling water temperature.

(6) Advanced phase sequence self-recognition function

(7) Abundant external control interface

(8) Simple and convenient debugging and maintenance

(9) Easy to operate, just turn a knob to turn on the machine.

(10) Voltage and current double closed-loop PID control and regulation system.

(11) Cooling method: water cooling. The water pressure is between 1.5-2Kgf/cm3, reliable cooling (each branch has temperature protection function). All equipment cooling pipelines are connected by stainless steel taps, which should be convenient and quick to install and disassemble. The water circuit is open circulation, and the cooling water tank is made of stainless steel. The installation height is 1.5 meters away from the bottom of the cabinet.

(12) Ensure that the power grid changes: 380 V±10% can work normally

(14) The equipment panel is equipped with incoming line voltmeter, intermediate frequency ammeter, intermediate frequency voltmeter, intermediate frequency power meter and power meter

(15) The technical parameters of the capacitor and the intermediate frequency transformer are matched with the intermediate frequency power supply. The capacitor adopts the all-film capacitor produced in Guilin (American technology).

(16) The power cabinet adopts a sealed method, and there are fluorescent lamps for maintenance inside, and there are knock-off holes for wire entry at the top and bottom, and the front and rear doors are equipped with sealing strips.

(17) The cable adopts water-cooled cable, and the hose adopts high pressure resistant tube.

(18) Various indicating signs are fixed with rivets.

(19) Insulation strength and withstand voltage, the main circuit-ground (shell) insulation resistance is not less than 1M

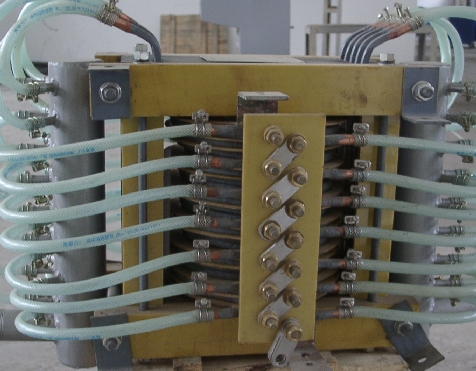

2. Description of the structure of the intermediate frequency transformer:

The intermediate frequency transformer adopts a new type (PR type) transformer, and the transformer core is made of 0.2-0.35mm thick high-permeability silicon steel sheets (3K sheets) stacked. The coils are wound in an overlapped manner. The turns ratio varies widely. The original and secondary sides can be changed according to It needs to be arbitrarily combined into odd and even turns ratios, and the load adaptability is strong. Both the transformer coil and the iron core have a water-cooled circuit.

Use conditions of large gear hardening machine

Power supply: 3Ф 380V±10% 50HZ three-phase four-wire system

2. Ambient temperature: 5-35℃

3. Altitude: less than or equal to 1000M

4. Relative humidity: <90%

5. Cooling circulating water: water pressure: 0.15-0.3Mpa

6. No conductive dust and corrosive gas