- 28

- Mar

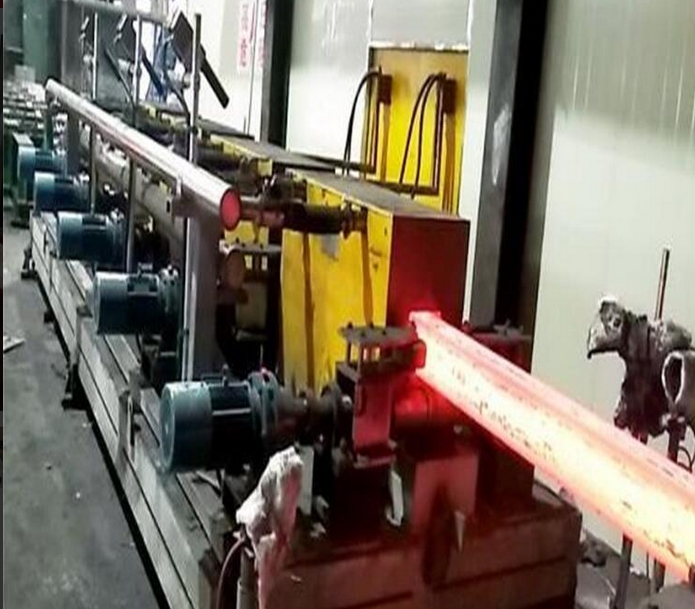

Bar heat treatment equipment

Bar heat treatment equipment

High-quality bar heat treatment equipment, our company specializes in the research and development, design, process, application, manufacturing and sales of induction heating equipment. We have rich experience and practical cases in bar heat treatment equipment. According to your manufacturing requirements, we will provide free To provide you with a complete set of bar heat treatment equipment solutions, to provide you with user application on-site video cases, etc., to meet your different requirements, welcome to come to consult!

Bar istilik müalicəsi avadanlığının əsas texniki parametrləri:

1. Enerji təchizatı sistemi: söndürmə enerji təchizatı + temperləşdirmə enerji təchizatı

2. The output per hour is 0.5-3.5 tons, and the applicable range is above ø20-ø120mm.

3. Daşınma çarxı masası: Rolikli masanın oxu və iş parçasının oxu daxil edilmiş 18-21° bucaq təşkil edir. İş parçası öz-özünə fırlanır və isitməni daha vahid etmək üçün sabit sürətlə irəliləyir. Ocaq gövdələri arasındakı roller masa 304 maqnitsiz paslanmayan poladdan hazırlanmışdır və su ilə soyudulur.

4. Roller table grouping: The feeding group, the sensor group and the discharging group are independently controlled, which is conducive to continuous heating without creating a gap between the workpieces.

5. Temperature closed-loop control: Both quenching and tempering adopt the closed-loop control system of the American Leitai infrared thermometer to accurately control the temperature.

6. Industrial computer system: Real-time display of the status of working parameters at that time, and functions of workpiece parameter memory, storage, printing, fault display, and alarm.

7. Energy conversion: quenching + tempering method is adopted, and the power consumption per ton is 280-320 degrees.

8. İnsan-maşın interfeysi PLC avtomatik ağıllı idarəetmə sistemi, “bir düyməli başlanğıc” istehsalı narahat olmadan.