- 28

- Mar

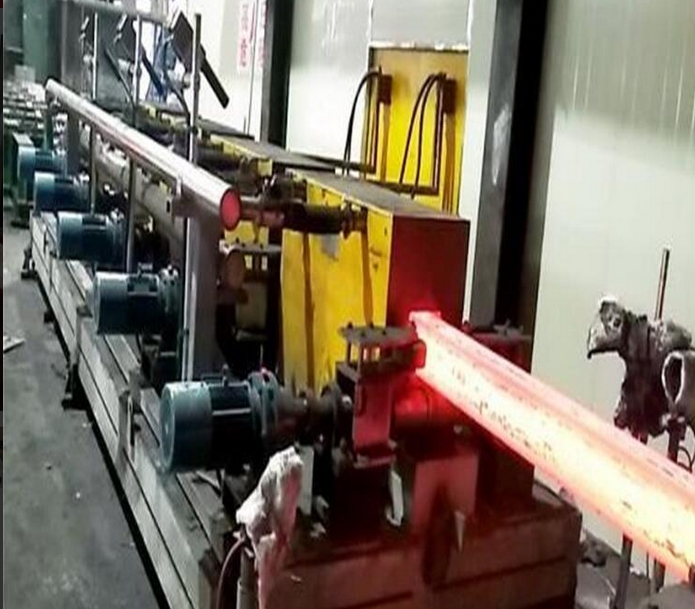

Bar heat treatment equipment

Bar heat treatment equipment

High-quality bar heat treatment equipment, our company specializes in the research and development, design, process, application, manufacturing and sales of induction heating equipment. We have rich experience and practical cases in bar heat treatment equipment. According to your manufacturing requirements, we will provide free To provide you with a complete set of bar heat treatment equipment solutions, to provide you with user application on-site video cases, etc., to meet your different requirements, welcome to come to consult!

Panguna nga teknikal nga mga parameter sa bar heat treatment equipment:

1. Sistema sa suplay sa kuryente: pagpalong sa suplay sa kuryente + tempering power supply

2. The output per hour is 0.5-3.5 tons, and the applicable range is above ø20-ø120mm.

3. Pagdala sa lamesa sa roller: Ang axis sa roller table ug ang axis sa workpiece usa ka gilakip nga anggulo sa 18-21 °. Ang workpiece nagtuyok sa iyang kaugalingon ug nagpadayon sa unahan sa kanunay nga tulin aron mahimo ang pagpainit nga mas uniporme. Ang lamesa sa roller tali sa mga lawas sa hudno gihimo sa 304 non-magnetic stainless steel ug gipabugnaw sa tubig.

4. Roller table grouping: The feeding group, the sensor group and the discharging group are independently controlled, which is conducive to continuous heating without creating a gap between the workpieces.

5. Temperature closed-loop control: Both quenching and tempering adopt the closed-loop control system of the American Leitai infrared thermometer to accurately control the temperature.

6. Industrial computer system: Real-time display of the status of working parameters at that time, and functions of workpiece parameter memory, storage, printing, fault display, and alarm.

7. Energy conversion: quenching + tempering method is adopted, and the power consumption per ton is 280-320 degrees.

8. Human-machine interface PLC automatic intelligent control system, “one-key start” production nga walay kabalaka.