- 28

- Mar

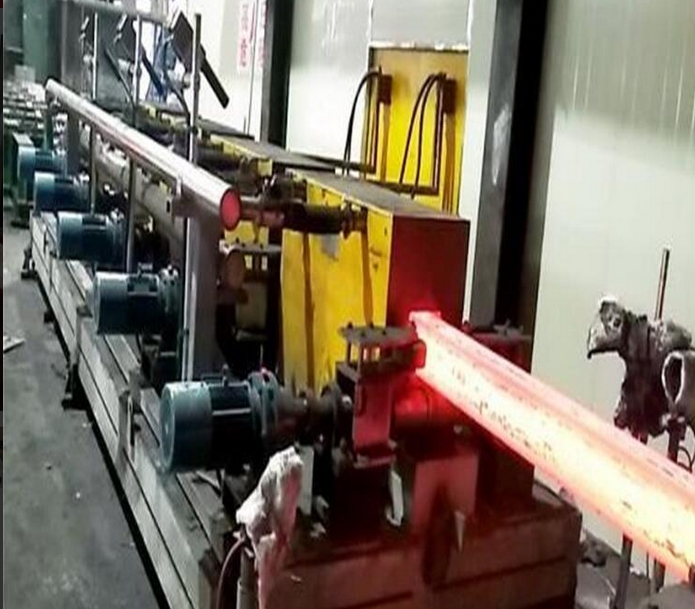

Bar heat treatment equipment

Bar heat treatment equipment

High-quality bar heat treatment equipment, our company specializes in the research and development, design, process, application, manufacturing and sales of induction heating equipment. We have rich experience and practical cases in bar heat treatment equipment. According to your manufacturing requirements, we will provide free To provide you with a complete set of bar heat treatment equipment solutions, to provide you with user application on-site video cases, etc., to meet your different requirements, welcome to come to consult!

Glavni tehnički parametri opreme za toplinsku obradu šipki:

1. Sistem napajanja: napajanje za gašenje + napajanje za kaljenje

2. The output per hour is 0.5-3.5 tons, and the applicable range is above ø20-ø120mm.

3. Transportni valjkasti sto: Osa valjkastog stola i osa radnog komada čine uključeni ugao od 18-21°. Radni predmet se sam rotira i kreće se naprijed konstantnom brzinom kako bi zagrijavanje bilo ravnomjernije. Rolo stol između tijela peći izrađen je od nemagnetnog nehrđajućeg čelika 304 i hlađen vodom.

4. Roller table grouping: The feeding group, the sensor group and the discharging group are independently controlled, which is conducive to continuous heating without creating a gap between the workpieces.

5. Temperature closed-loop control: Both quenching and tempering adopt the closed-loop control system of the American Leitai infrared thermometer to accurately control the temperature.

6. Industrial computer system: Real-time display of the status of working parameters at that time, and functions of workpiece parameter memory, storage, printing, fault display, and alarm.

7. Energy conversion: quenching + tempering method is adopted, and the power consumption per ton is 280-320 degrees.

8. Interfejs čovjek-mašina PLC automatski inteligentni kontrolni sistem, “pokretanje jednim ključem” proizvodnja bez brige.