- 09

- Jun

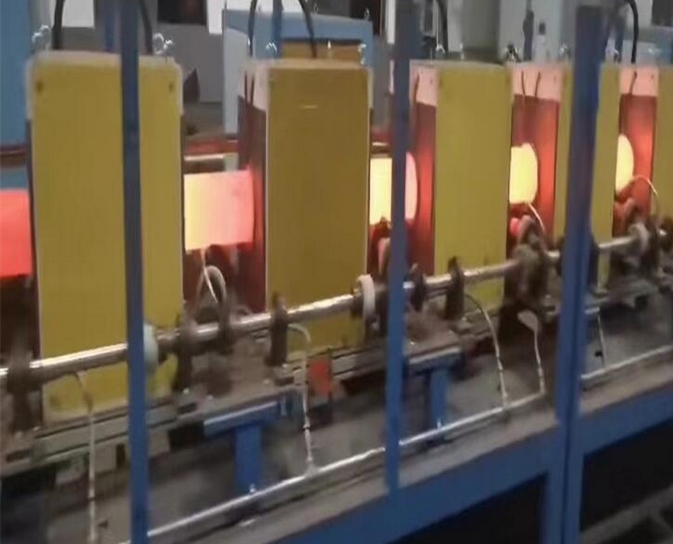

Features of steel bar forging diathermy furnace:

Features of steel bar forging diathermy furnace:

1. Less oxidative decarburization during the heating process of the steel bar: Since the heat is generated inside the heated workpiece, the heating rate is fast, the efficiency is high, and the surface of the workpiece is less oxidized and decarburized, saving raw materials.

2. The overall heating temperature of the steel bar is uniform, the temperature control accuracy is high, the temperature difference is small, and there is no pollution:

3. The heating temperature control accuracy of the round steel is extremely high and the temperature difference between the core and the surface is low, so there will be no harmful gas, smoke, strong light and other pollution of the environment during the production process.

4. The diathermy electric furnace for steel bar forging has a 100% start-up success rate and high reliability: at the beginning of heating, it can be started directly and quickly at any temperature (cold/hot) and under any load (with billet in the induction furnace/without billet). The startup success rate is 100%. And through the automatic temperature compensation technology, the temperature rises rapidly to avoid the loss of startup waste and improve the production efficiency. At the end of heating, the furnace can be emptied from full load to no-load, and then a qualified billet: when a billet enters the induction furnace, the output power can be automatically adjusted under the condition of constant changes in the furnace load, so that the billet temperature is stable and maintained. Its constant temperature output, while continuing to heat, completely empties the last qualified billet in the induction furnace, avoiding the loss of waste during shutdown.