- 09

- Jun

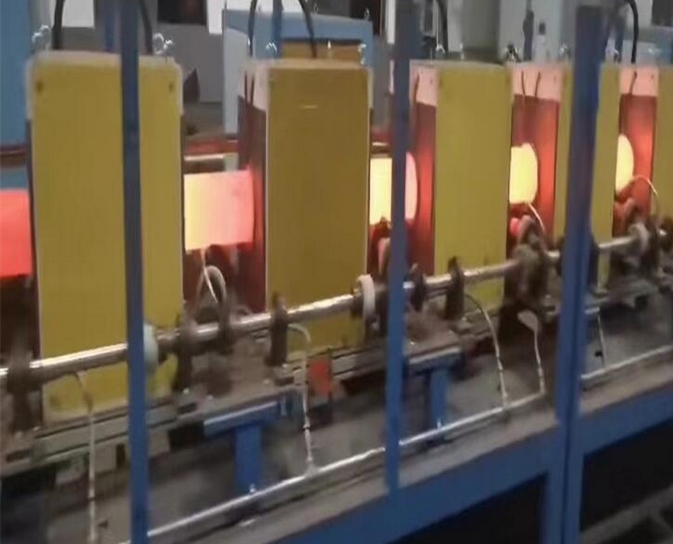

Iimpawu zentsimbi yokwenza isithando somlilo se-diathermy:

Iimpawu zentsimbi yokwenza isithando somlilo se-diathermy:

1. Ubuncinci be-oxidative decarburization ngexesha lokufudumeza kwebar yentsimbi: Ekubeni ubushushu buveliswa ngaphakathi kwendawo yokusebenza eshushu, izinga lokufudumeza liyakhawuleza, ukusebenza kakuhle kuphezulu, kwaye umphezulu we-workpiece awunayo i-oxidized encinci kwaye i-decarburized, igcina imathiriyeli ekrwada. .

2. Ubushushu obupheleleyo bobushushu bentsimbi yentsimbi bufana, ukuchaneka kokulawula ubushushu kuphezulu, umahluko weqondo lobushushu umncinci, kwaye akukho ngcoliseko:

3. Ukuchaneka kokulawula ubushushu bokushisa kwentsimbi ejikelezileyo kuphezulu kakhulu kwaye umehluko weqondo lokushisa phakathi kwengundoqo kunye nomphezulu uphantsi, ngoko ke akuyi kuba negesi eyingozi, umsi, ukukhanya okunamandla kunye nokunye ukungcola kokusingqongileyo ngexesha lenkqubo yokuvelisa.

4. Isithando sombane se-diathermy sombane we-bar forging sine-100% yezinga lokuphumelela lokuqala kunye nokuthembeka okuphezulu: ekuqaleni kokufudumeza, inokuqaliswa ngokuthe ngqo kwaye ngokukhawuleza kuyo nayiphi na iqondo lokushisa (kubanda / kushushu) naphantsi kwayo nayiphi na imithwalo (kunye i-billet kwisithando somlilo / ngaphandle kwe-billet). Izinga lokuphumelela lokuqalisa li-100%. Kwaye ngetekhnoloji yembuyekezo yobushushu obuzenzekelayo, ubushushu bukhuphuka ngokukhawuleza ukuphepha ukulahleka kwenkunkuma yokuqalisa kunye nokuphucula ukusebenza kakuhle kwemveliso. Ekupheleni kokufudumeza, isithando somlilo sinokukhutshwa kumthwalo ogcweleyo ukuya kukungabikho komthwalo, kwaye emva koko i-billet efanelekileyo: xa i-billet ingena kwisithando somlilo, amandla okukhutshwa angakwazi ukulungiswa ngokuzenzekelayo phantsi kweemeko zokutshintsha rhoqo kumthwalo wesithando somlilo. , ukwenzela ukuba ukushisa kwe-billet kuzinzile kwaye kugcinwe. Imveliso yayo yokushisa eqhubekayo, ngelixa iqhubeka nokufudumala, ikhupha ngokupheleleyo i-billet yokugqibela efanelekileyo kwi-furnace induction, ukuphepha ukulahlekelwa kwenkunkuma ngexesha lokuvalwa.