- 12

- Oct

Kev siv hluav taws xob kho cua sov daim ntawv thov 11 kev lag luam loj, koj puas paub?

Kev siv hluav taws xob kho cua sov daim ntawv thov 11 kev lag luam loj, koj puas paub?

1. Kev Lag Luam Kev Tsim Tsheb

Kev lag luam tsheb tau nthuav dav tshaj plaws siv cov txheej txheem kho cua sov, thiab induction cua sov thiab quenching ntawm qhov chaw pib tau nce mus txog 50% ntawm txhua qhov kho cua sov. Ntxiv rau kev txhim kho qhov hnav tsis kam ntawm qhov chaw, lub hom phiaj ntawm induction hardening yog txhawm rau ua kom lub zog torsional qaug zog thiab khoov qaug zog ntawm qhov chaw. Cov feem raug suav nrog crankshafts, camshafts, flywheel ring gear, ib nrab shafts, qhov nrawm nrawm thoob ntiaj teb sib koom ua ke, hloov rab diav rawg, xa cov ncej, hla cov ncej, poob siab absorbers, thiab lwm yam.

2. Tsheb laij teb thiab siv tshuab ua haujlwm

Tshwj tsis yog tias lub cav quenching qhov zoo ib yam li lub cav tsheb, muaj ntau qhov induction quenching ntu hauv kev taug kev: xws li tsav lub log, qhia lub log, txhawb nqa lub log, txuas cov tsheb nqaj hlau txuas, pins, tes tsho, cov twj tso kua dej tso tawm, valve rocker caj npab tsheb nrau av, thiab tsheb laij teb. Kev xa cov zog, thiab lwm yam.

3. Tshuab Kev Lag Luam Kev Lag Luam

Hauv kev tsim cov cuab yeej siv tshuab, cov khoom siv tawv tawv suav nrog lub taub hau lub zog, ntxaiv, rab diav rawg, qhia cov tsheb nqaj hlau thiab cov khoom tiv taus ntawm ntau yam me me.

4. Hnyav Machinery

Heavy machinery induction kho cua sov qhov chaw suav nrog: kis loj modulus zog, duav hniav phaj ntawm excavators.

5. Cov kabmob kev lag luam

Kev faib ua feem ntawm cov kabmob sib dhos, tshwj xeeb tshaj yog cov kev sib tw ntawm cov kabmob loj thiab cov kabmob tsheb nqaj hlau uas siv qhov sib zog ua kom hnyav, yog nce xyoo ib xyoo.

6. Tsheb thauj mus los

Kev tua hluav taws tag nrho ntawm 60kg thiab cov kab saum toj no yog ib txoj hauv kev tseem ceeb los txhim kho lawv lub zog thiab tawv. Ministry of Railways tau tsim ntau dua 10 txoj kab hluav taws xob induction quenching cov kab ntau lawm. Ib qho ntxiv, cov khoom siv hauv tsheb yog cov khoom siv tawv tawv uas cuam tshuam nrog lub cav sib txuas sab hauv, xws li crankshafts, zog, ncej, thiab lwm yam.

7. Roj Rig

Cov kav dej roj, cov pas nqus dej thiab cov khoom sib txuas siv hauv kev lag luam roj av yog txhua yam ua kom tawv.

8. Metallurgical Machinery

Cov yob txais yuav ob-zaus induction hardening kom ua tiav qhov cua sov zoo tshaj plaws. Lwm yam xws li cov cuab yeej loj-modulus, cov yeeb nkab hlau txuas tau raug kho lossis ua kom sov.

9. Textile Machinery

Spinning tshuab ntxaiv thiab lwm qhov chaw txais induction hardening thiab kub.

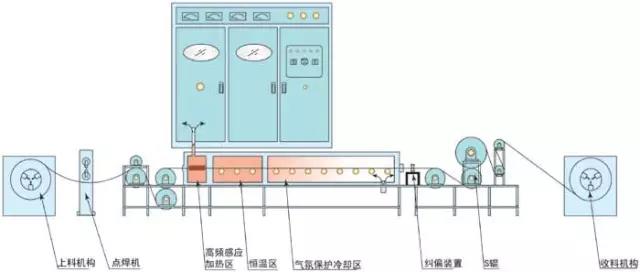

10. Khoom Siv Tsev

Muaj feem ntau yog pre-stress steel quenching thiab welding seam annealing. Daim duab 1-2 qhia txog daim duab qhia kev ntawm lub PC steel quenching thiab ua kom sov cov kab ntau lawm. Muaj ntau tus lej ntawm cov yeeb nkab pawg hlau hlau kho cua sov cov kab tsim tau tsim nyob hauv Suav teb, thiab pw tsaug zog hlau xaim hluav taws xob kho cua sov cov kab tsim tawm tau tsis ntev los no tau ntxiv.

11. Shipbuilding kev lag luam

Induction hardening thiab tempering yog siv rau marine cav crankshafts, thiab lwm yam.