- 12

- Oct

Induction heat treatment technology application 11 major industries, which do you know?

Induction heat treatment technology application 11 major industries, which do you know?

1. Automobile Manufacturing Industry

The automotive industry has most widely adopted induction heat treatment technology, and induction heating and quenching of auto parts has risen to about 50% of all heat-treated parts. In addition to improving the wear resistance of parts, the purpose of induction hardening is to increase the torsional fatigue strength and bending fatigue strength of parts. Typical parts include crankshafts, camshafts, flywheel ring gears, half shafts, constant velocity universal joints, shift forks, transmission shafts, cross shafts, shock absorber shafts, etc.

2. Tractors and construction machinery

Except that the engine quenching parts are similar to the automobile engine, there are many induction quenching parts in the walking part: such as driving wheels, guide wheels, supporting wheels, chain rail links, pins, sleeves, water pump shafts, valve rocker arms, bulldozer blades, and tractors. Transmission gears, etc.

3. Machine Tool Manufacturing Industry

In the machine tool manufacturing industry, induction hardened parts include the headbox gears, spindles, gear forks, guide rail surfaces and wear-resistant parts of various small parts.

4. Heavy Machinery

Heavy machinery induction heat treatment parts include: transmission large modulus gears, shovel tooth plates of excavators.

5. Bearing industry

The proportion of bearing rings, especially the raceways of large-scale bearing rings and railway bearings using induction hardening, is increasing year by year.

6. Railway transportation

Full-length quenching of 60kg and above rails is one of the main ways to improve their strength and toughness. The Ministry of Railways has established more than 10 rail induction quenching production lines. In addition, locomotive parts are induction hardened parts related to internal combustion engines, such as crankshafts, gears, shafts, and so on.

7. Oil Rig

The oil pipes, sucker rods and coupling parts used in the petroleum industry are all induction hardened.

8. Metallurgical Machinery

The roll adopts dual-frequency induction hardening to achieve the best heating depth. Others such as large-modulus gears, steel pipe welds are annealed or tempered.

9. Textile Machinery

Spinning machine spindles and other parts adopt induction hardening and tempering.

10. Building Materials

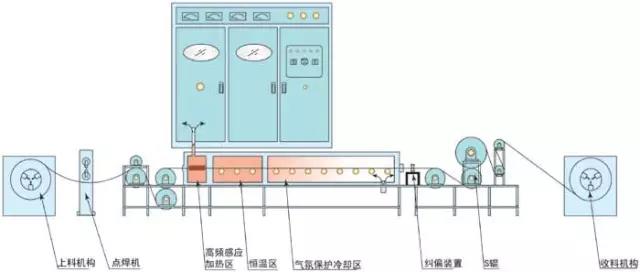

There are mainly pre-stressed steel quenching and welding seam annealing. Figure 1-2 shows the schematic diagram of the PC steel quenching and tempering production line. A considerable number of pipe pile steel wire heat treatment production lines have been established in China, and sleeper steel wire heat treatment production lines have recently been added.

11. Shipbuilding industry

Induction hardening and tempering are used for marine engine crankshafts, etc. Induction heating can also be used for thermal correction of steel plate distortion.